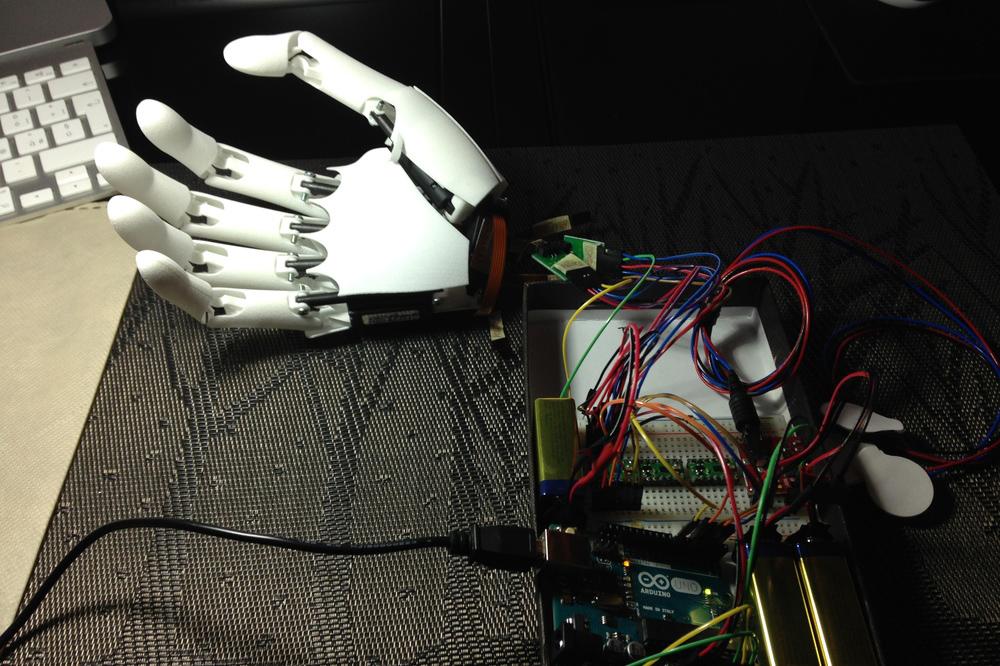

With Iron Man looking on, Italian technology designer Federico Ciccarese holds a white plastic hand rigged with multicolored wires attached to an electronic switchboard. He is about to start a demo of his YouBionic hand. In the window behind him, the sun is setting — it’s evening in Milan — and to his left, a life-size poster of Tony Stark in full metal garb.

“He’s my assistant,” Ciccarese jokes. “And also my hero and inspiration because he cared about humanity.”

He turns on the hand, and its white chalky fingers clench into a fist. Then they unclench and the palm is open again. Finally, the index finger and the thumb form a circle, as if holding a small, delicate object.

We take these moves for granted; we all do them a thousand times a day without thinking.

We take these moves for granted; we all do them a thousand times a day without thinking. But for people who have lost hands or fingers, these simple actions are unattainable. Grasping a doorknob is impossible, let alone holding a pen or counting change. Ciccarese set off to fix this problem. His YouBionic hand may look like science fiction, but the mechanism is surprisingly simple, he says.

When we want to wrap our fingers around a glass or pick up a piece of paper, our brain sends signals to our muscles. These signals travel through our central nervous system to the muscles in a form of electrical impulses. In a healthy person’s body, these signals result in the appropriate muscle contractions such as fingers moving and bending. In an amputee’s body, the brain still generates the signals, but they don’t reach the destination, because the body parts aren’t there. But if you attach electrodes to the muscle of the remaining part of an amputee’s arm, you can read the impulses and translate them into the movements of the hand—albeit a plastic one.

The electrical impulses differ in strength, which translates into the contractions of different scale and movements of different range: lower impulses result in smaller movements, higher impulses in larger ones.

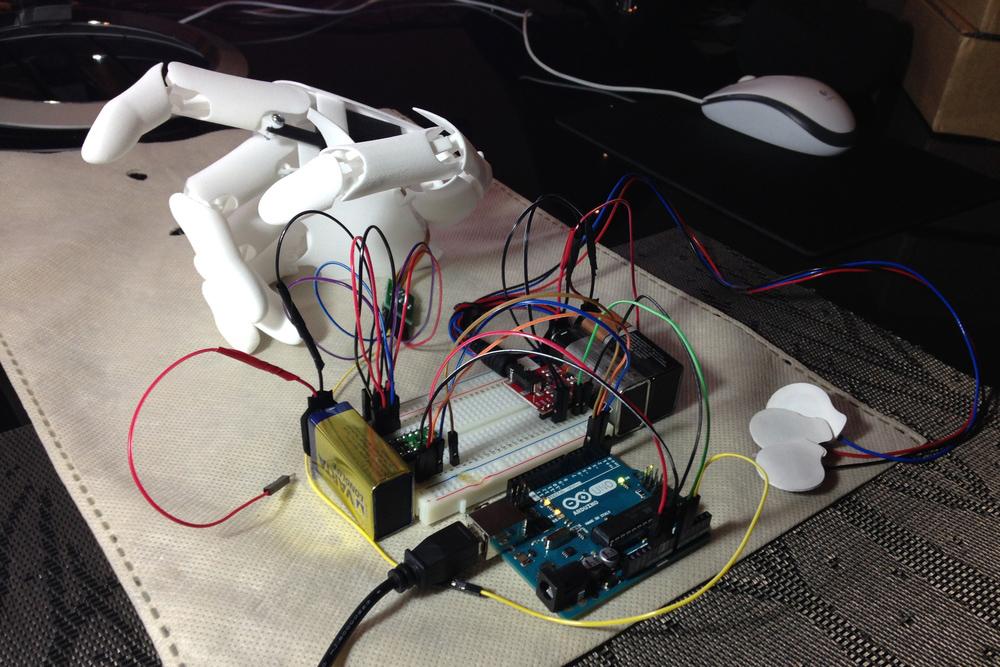

This conversion is pretty straightforward, Ciccarese says, thanks to Arduino, a type of microcontroller which allows creating robotic devices that interact with the world using sensors that suck up information (in this case via electrodes), and actuators—the little motors that make mechanical parts move. “There’s electricity in all muscles of our body,” Ciccarese says. “When the brain sends an impulse to the muscle, the sensor reads it and translates it into a number proportional to the contraction and then sends this message to the microcontroller.”

It takes three electrodes to read one muscle’s electrical impulses. To make the YouBionic hand operate, Ciccarese places the red electrode at the center of the muscle, the blue at the end, and the black one toward the bone close to the muscle. In the future, to improve the movements, he plans to use electrodes on multiple muscles.

He envisions amputees being able to update the hardware and software of their limbs the way we update our smartphones.

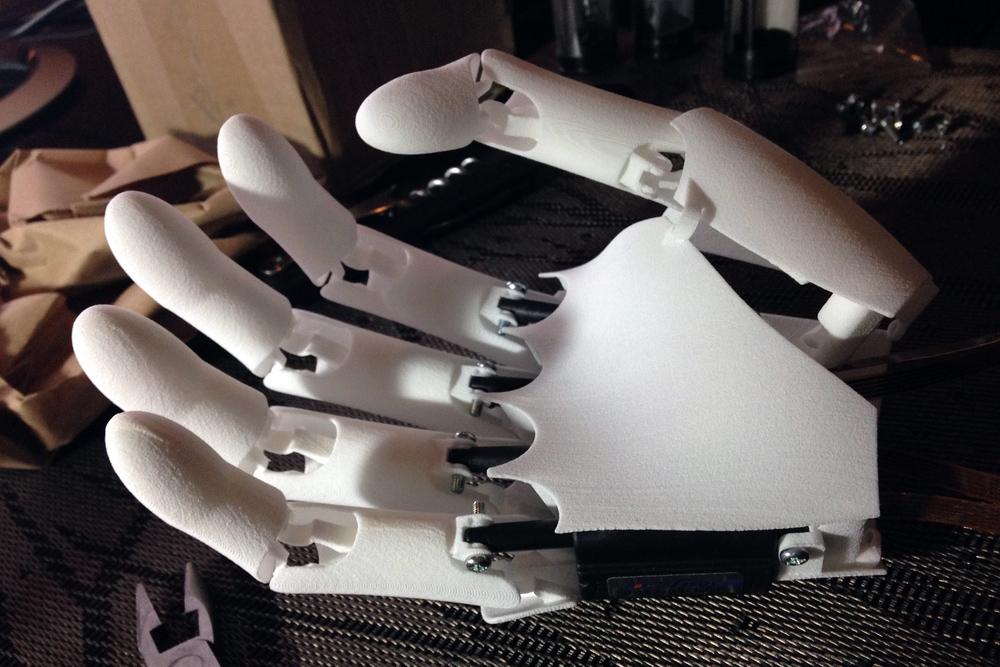

But that’s only part of the YouBionic hand’s appeal. The other is the simplicity of manufacturing. Its plastic parts are 3D-printed from nylon dust. In a process called sintering, a laser 3D printer heats up the dust and molds it into the required plastic parts. “Right now I send a drawing to a company that prints it,” says Ciccarese, but in the future it can be done at home. With slightly different 3D technology such as Fused Deposition Modeling that builds parts by layering plastic, YouBionic customers would be able to 3D-print their hand pieces themselves, easily and cheaply. Arduino, which runs on open-source hardware, is also inexpensive, so Ciccarese expects YouBionic hands to be very affordable.

He envisions amputees being able to update the hardware and software of their limbs the way we update our smartphones. If there’s an update to the Arduino software that makes your finger clench faster, just download the code. If there’s an upgrade for the thumb that gives you a better grip on your pen, 3D-print the new thumb part and toss away the outdated one.

“In the future people will be able to update their bionic hand by downloading and printing the latest 3D model,” he says. Right now, the hand is all plastic, except for wires, but he plans to add rubber spots onto it to improve the pinch grip action.

Ciccarese says that his technology can be scaled for foot amputees as well. But he also takes it a step further. He imagines that even healthy humans may find a third hand useful in some situations. Why not give an extra hand — a robotic indestructible extremity that doesn’t feel pain — to a fireman or someone else operating in extreme conditions? And astronauts repairing the surfaces of their ships might find hands operating outside their suits handy, too.

“I started this device as a prosthetic, but it can have many applications,” Ciccarese says. “I hope I can do something for humanity like the Iron Man.”

A boat designer by day and robotic aficionado by night, Ciccarese began experimenting with the bionic hand about a year ago. “I am 33 years old. Designing boats is good, why not, but I wanted to do something important for humanity,” he says, adding that he plans to let amputees test YouBionic in 2015.

“On Twitter, I talked to a father of a 5-year-old who is missing five fingers. He is waiting for me to finish this, so his son can try it.”

Editors' Recommendations

- 3DMakerpro’s Seal is a pocket-sized scanner to make next-gen precision 3D prints

- Need a last-minute Halloween costume? Check out these 3D-printable getups

- The future of making stuff: Inside the evolution of 3D printing with Formlabs

- Father’s Day Gift Idea: These cheap 3D printers are on sale for less than $300

- The 50-year old Silicon Valley lab that practically invented modern computing