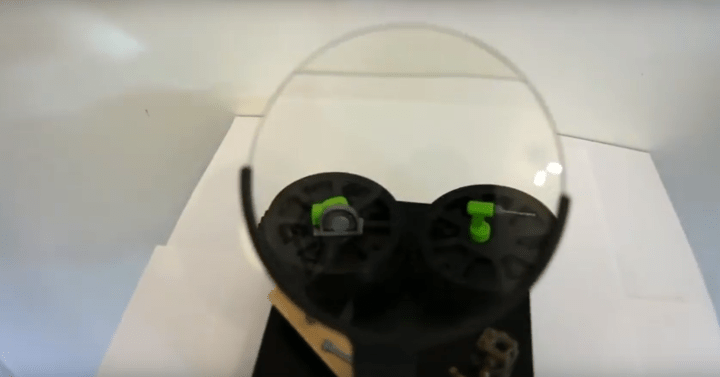

The tiny working power tool took just under hour to print, and is manufactured in four distinct pieces — two parts contain the main housing, a saw guard, and a blade holder. These are, as one would imagine, the same components that make up a normal-sized circular saw, just shrunken to laughable proportions. To turn it on, simply press a button on the handle, and you’ll be prepared to cut the world’s smallest piece of wood.

Speaking with 3Dprint.com, Abernethy said, “The saw was just a natural progression from the drill. I would like to be able to make a whole set of power tools just like my Makita set I have. I’m not sure how many I will get around to making though.” It is also unclear exactly what purpose these miniature tools would serve, other than being remarkable for their size. Abernethy himself has admitted that in its current form, the circular saw is incapable of actually performing the functions of a saw — that is to say, cutting through things.

Still, it’s yet another demonstration of the capabilities of good design and 3D printers, and Abernethy still seems to have a few tricks up his sleeve. He noted, “I actually made this a few months ago and will start making more stuff soon, once I get back into 3D printing. I will eventually get around to making something with parts people can easily buy and print, and then do a tutorial on how to make it.”

So while you may need to turn yourself into a miniature version of a human to utilize these tools, rest assured that there are still more to come. And who knows — maybe they’ll serve a purpose that we’ve yet to imagine.

Editors' Recommendations

- 3D printed cheesecake? Inside the culinary quest to make a Star Trek food replicator

- AMD’s revolutionary 3D V-Cache chip could launch very soon

- Fighting football injuries with 3D-printed, hyper-personalized pads

- Need a last-minute Halloween costume? Check out these 3D-printable getups

- NASA is testing a 3D printer that uses moon dust to print in space