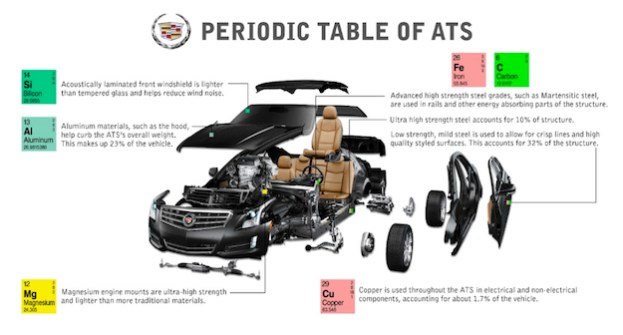

This morning Cadillac put out a release about the “ultra high-strength” materials used in the 2013 ATS. It’s not the shortest press release in history, but it’s darn near close. What the press release lacks in verse, it more than makes up for in the snazzy blow out that you see above: “Periodic Table of ATS.”

Including silicon, aluminum, magnesium, copper, iron, and carbon, the ATS is one of the lightest vehicles in its class – and one of the safest, too. The National Highway Traffic Safety Administration gave the ATS a five-star crash rating in its New Car Assessment Program (NCAP).

What role do all these special materials play in the ATS? Let’s break it down. Silicon is used in the windshield to help reduce wind noise. Lightweight aluminum makes up 23 percent of the total vehicle construction. Magnesium has been used for engine mounts that are lighter and more durable than mounts of the past. Ultra high-strength steel makes up 10 percent of the ATS, which is formed from iron and carbon. Another 32 percent is mild-grade steel, which Cadillac says allows for the ATS’ crisp bodylines. Lastly, copper is used throughout the electrical system.

We’ve actually already reviewed the 2013 Cadillac ATS, and although the 3.6-liter V6 produces 321 horsepower, it certainly feels like a lot more. This is thanks to, in large part, the low curb weight of the ATS. Additionally, the high-strength rigid chassis makes the ATS a very planted, confidently handling mid-size sedan.

Although we had a chuckle at the brevity of the Cadillac press release, we do applaud the Cadillac folks for putting together a cool breakdown of the materials used in their newest vehicle. You can tell they’re proud of it, and rightfully so.

Editors' Recommendations

- GM to cut funding for beleaguered driverless startup Cruise, report claims

- Everything is bigger in Cadillac’s electric Escalade IQ

- General Motors enters the used car game with CarBravo

- Cadillac’s 2020 CT4 small sedan starts at $33,990, sporty V model tops $40,000

- Delaminated touchscreens in some 2013-2017 Cadillacs prompt class-action lawsuit