Even the most dedicated gearhead can’t restore a classic car without the right parts. The older and/or rarer the car, the harder it is to find parts for. But Porsche is using new technology to keep its old cars on the road, by 3D printing new parts that would not otherwise be available.

Even the most dedicated gearhead can’t restore a classic car without the right parts. The older and/or rarer the car, the harder it is to find parts for. But Porsche is using new technology to keep its old cars on the road, by 3D printing new parts that would not otherwise be available.

The automaker’s Porsche Classic division currently stocks around 52,000 parts for various vintage Porsche models. When parts are no longer in stock, the company makes new ones using traditional production methods. But that’s only economical for large production runs. When just a small number of parts are needed, Porsche feels that 3D printing is the way to go. Parts can be made on demand, eliminating the cost of tooling for a conventional production run, as well as storage costs.

For example, Porsche 3D printed a new clutch release lever for the 959. That model was Porsche’s first true supercar, boasting a top speed of 200 mph. Only 292 were made (Bill Gates was among the original customers), so demand for spare parts isn’t exactly stratospheric. But 3D printing allowed Porsche to make replacements for the clutch release lever available to any owners that might need one, without having to tool up for an expensive conventional production run.

To make the lever, Porsche starts out with powdered tool steel. The powder is spread in a thin layer on a plate, and then melted with a laser beam to create a layer of finished material. That process is repeated layer by layer until the part is finished. Each 3D-printed part goes through a series of tests, including tomographic imaging, load testing, and a test drive on an actual car, to ensure it’s up to snuff.

In addition to the 959 clutch release lever, Porsche said it is currently 3D-printing eight other parts from either steel or plastic. It is testing whether 3D printing can be used to reproduce an additional 20 parts. All it takes to reproduce a part is a 3D scan, so in theory the sky’s the limit.

Porsche isn’t the only automaker experimenting with 3D printing. Mercedes-Benz uses 3D printing to reproduce hard-to-find parts for older commercial trucks, and Ford is considering using the technology to help customers personalize their cars. Local Motors even 3D printed the entire body of an electric car. So far, small-batch, specialty applications seem to be the best fit for 3D printing in automotive manufacturing.

Editors' Recommendations

- Nvidia turns simple text prompts into game-ready 3D models

- 3D printed cheesecake? Inside the culinary quest to make a Star Trek food replicator

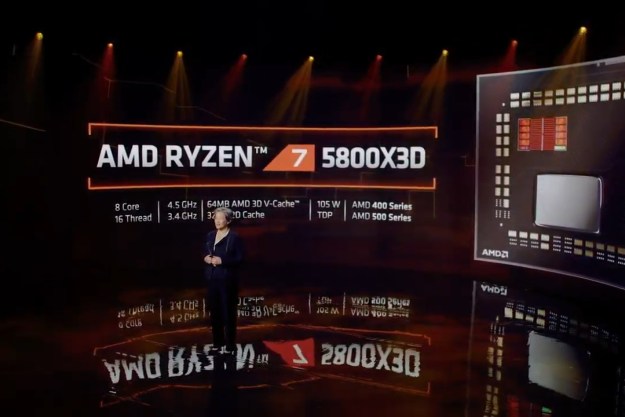

- AMD Ryzen 7 5800X3D beats predecessor, but AMD promised more

- AMD’s revolutionary 3D V-Cache chip could launch very soon

- AMD teases performance of its revolutionary 3D V-cache chip