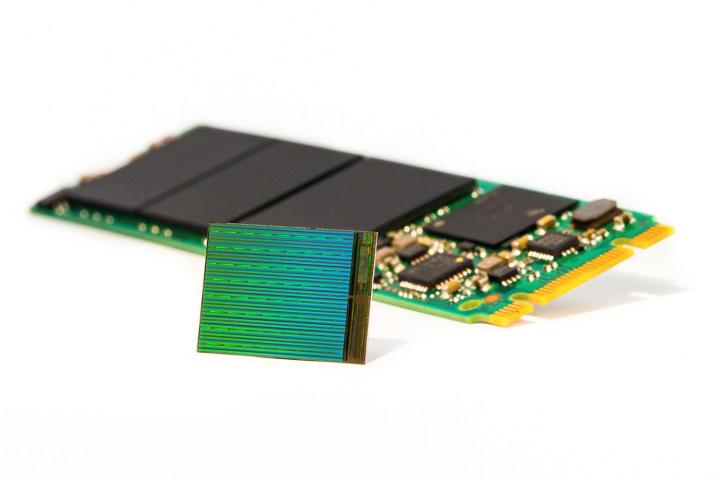

Instead of the old planar method, where bits are laid out flat on a silicon wafer, manufacturers are moving towards 3D NAND, where the bits are stacked vertically. That means more memory in a smaller space, but a recent study by Stifel, an market research firm, found that in order for it to happen, manufacturers are making huge investments in the fabrication of the technology, a necessary step before production can begin in force. Investments that may not pay for themselves, even after years of sales and production.

One of the issues with producing 3D NAND chips is that they’re more complex than planar chips by a significant margin. While the previous generation of flash memory took only three or four deposition layers to build, 3D NAND takes between 120 and 144, according to the study. When you’re dealing with that many steps in an already complicated process, there’s a lot that can go wrong. Not every wafer ends up as a usable die, which can mean huge losses when they’re so expensive to produce in the first place. It’s hard to say how high those losses could be, considering that foundry operators keep yield percentages private.

That cost is only compounded when you consider the staggering amount that companies like Samsung, Intel, and Toshiba have already planned to spend on the new infrastructure. According to the Stifel study, the major brands have already planned over 18 billion dollars in spending to produce 3D NAND chips over the next few years. That’s a hefty investment, even by computing and chip manufacturing standards.

3D NAND isn’t going to immediately lead to big, cheap drives.

So what does this mean for you? 3D NAND chips will gradually become more popular until they pass planar construction in market share, but even through 2018 their supply may remain limited, and their cost will be high. It also means that memory with planar construction will stay in demand because of its lower price point. In short, 3D NAND isn’t going to immediately lead to big, cheap drives. The companies investing in the technology will need to recoup their investment first.