When we first heard that NASA had plans to take a 3D printer into space in 2014, our first reaction was: Awesome! Our second reaction was: How the heck can you 3D print in space? Won’t the plastic material float up in the air in zero gravity? In a video published yesterday by NASA Marshall TV, our questions were mostly answered (although we’re a little confused by the disco tunes in the background, but that’s another story).

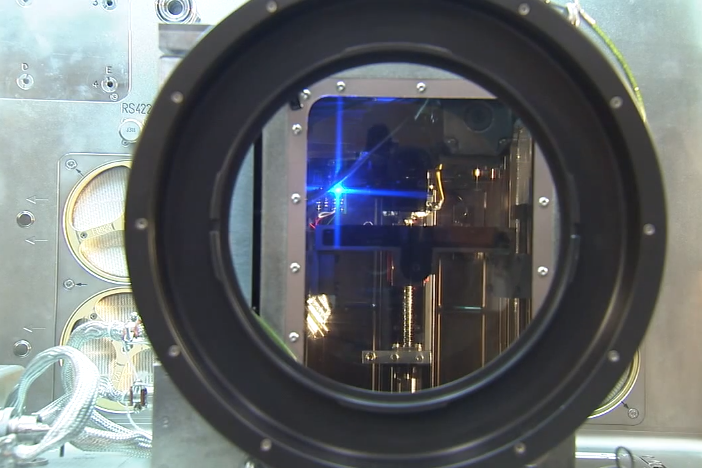

NASA has designed and built its own additive manufacturing printer that has a footprint of about a square foot. You might be thinking that bringing a 3D printer on the International Space Station is a little frivolous, bit it’s actually very useful. In space, whatever the astronauts have available in orbit is what they have – there are no hardware stores in space. But parts get lost or break, and when they do, there’s a long wait for replacement parts if they don’t already have a backup on board. With a 3D printer, however, the astronauts can 3D-print some of the parts that they need, eliminating the wait time for the new item. The printer contains preloaded plans for common parts, and the astronauts can even receive new plans from Earth if they need something not already pre-made.

“3D printing provides us with the ability to be able to do our own Star Trek replication right there on the spot to help us replace things we’ve lost, replace things we’ve broken, or maybe make things we’ve thought of that can be useful,” astronaut Timothy Creamer explains in the video.

According to Jason Dunn, CTO of Made in Space (the company responsible for designing the hardware), the printer recently underwent a set of tests through the NASA Flight Opportunities program, where they flew the printer on zero gravity parabolic flights, verifying that the design of their printer works in microgravity. Looks like the printer is ready for takeoff.

We’re pretty sure only one of these 3D-printable household items would be useable in orbit, but NASA should consider the Finger Fork if their space forks go missing. Check out the video below to see the printer in action.

Editors' Recommendations

- How to watch NASA and SpaceX launch Crew-7 to the space station

- Relativity Space launches first 3D-printed rocket, but it didn’t end well

- Check out this cool NASA image of SpaceX Crew-3’s ride home

- Watch highlights of SpaceX Crew-3’s arrival at the space station

- Watch the key moments of SpaceX’s Crew-3 launch to space station