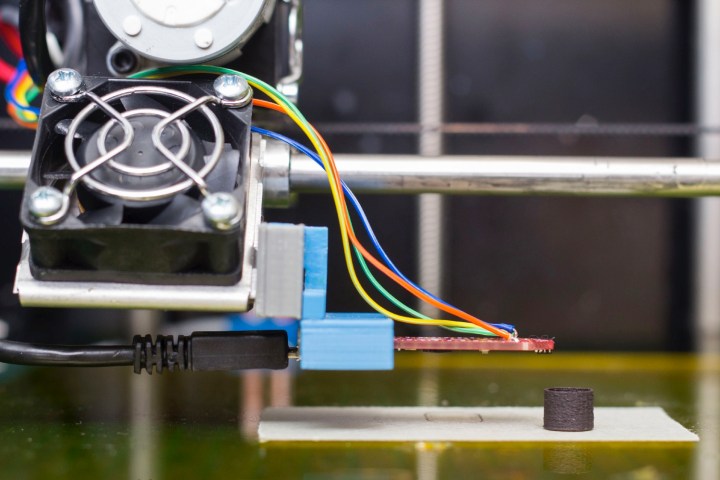

That looks set to change, though, courtesy of researchers at Vienna University of Technology, who have come up with a way to print permanent magnets using a regular 3D printer. In a project funded by the company Magnetfabrik Bonn, researchers were able to design a digital 3D model of the magnet they wanted to print, and then make it a reality using an off-the-shelf 1,500-euro Builder 3D printer and their own magnetic filament.

The filament is composed of approximately 90-percent magnetic material and 10-percent plastic. It is then subjected to a strong external magnetic field, thereby transforming it into a permanent magnet.

“This will enable the use of rapid prototyping to try out different designs of permanent magnets,” Dr. Dieter Süss, head of the university’s Christian-Doppler Advanced Magnetic Sensing and Materials Laboratory, told Digital Trends. “In some cases, it will be possible to come up with designs that could not be achieved by current injection molding techniques.”

“This filament is compatible with almost all commercially available printers,” he continued. “All that is needed is for someone to produce it. We hope that in the near future, you’ll be able to buy a magnetic filament in exactly the same way you can buy a non-magnetic one at the moment. Users will then be able to print any magnets they need at home, to fit any shape requirements that they have. This can be done by anyone.”

Things don’t stop there, though. The process of 3D-printing magnets isn’t just about making it more straightforward for people to build magnets — it can also make magnets better. For example, the research presents the possibility of using multiple materials within a single magnet to create a smooth transition between strong and weak magnetism.

“Long-term the plan is to be able to print every pixel of the 3D-printed magnet with its own magnetization direction,” Süss concluded. “This will be a completely new type of magnet that we will be able to fabricate, far beyond what it is possible to do right now. You’ll be able to design completely new magnetic fields which can’t be carried out by any other fabrication process right now.”

Editors' Recommendations

- Nvidia turns simple text prompts into game-ready 3D models

- AMD is bringing 3D V-Cache back to Ryzen 7000 — but there’s a twist

- AMD Ryzen 7 5800X3D beats predecessor, but AMD promised more

- AMD’s revolutionary 3D V-Cache chip could launch very soon

- AMD teases performance of its revolutionary 3D V-cache chip