A 3D-printed cement paste could one day be used to make buildings more resilient to natural disasters, claim researchers from Purdue University. Although it sounds paradoxical, the paste actually gets tougher the more it cracks. This makes it a potentially invaluable new building material.

“Cement-based materials such as concrete are brittle and crack as they deform,” Reza Moini, a doctoral candidate in the Lyles School of Civil Engineering at Purdue, told Digital Trends. “Using the findings of this work, we can produce structural elements for buildings and habitats that can resist dynamic loads such as impact, experienced during [an] earthquake, without failure.”

Jan Olek, a professor of civil engineering and another researcher on the project, noted that nature has to deal with weaknesses to survive, so the team is using the “built-in” weaknesses of cement-based materials to increase their toughness. They have done this by creating 3D-printed materials inspired by the properties found in arthropod shells, the shells belonging to animals such as lobsters and beetles. The biomechanical design of these shells allows them to take large amounts of punishment.

Some patterns which the printed paste could be used to replicate include honeycomb patterns or printed filaments following a helicoidal pattern. “3D printing has removed the need for creating a mold for each type of design, so that we can achieve these unique properties of cement-based materials that were not possible before,” said Jeffrey Youngblood a professor of materials engineering at Purdue.

This isn’t the first time we’ve covered innovative or futuristic building materials. Other research projects in this vein have included spray-on cement able to help older buildings survive earthquakes, and a smart graphene coating which changes color to indicate breaks and fractures.

“There are several questions and opportunities that we still need to answer,” Pablo Zavattieri told us. “We still do not understand the role of the rheological properties of fresh cement paste — as it is being extruded through the 3D printer, and it is deposited and put at rest on top of the already printed structure. We also do not know the properties of the new architectured materials during the first hours and days, as the cement paste goes through [its solidification] process. This involves all kind of mechanisms at different length scales, such as shrinkage and drying. We are going to explore the role of controlling weak interfaces.”

A paper describing the work was recently published in the journal Advanced Materials.

Editors' Recommendations

- Nvidia turns simple text prompts into game-ready 3D models

- 3D printed cheesecake? Inside the culinary quest to make a Star Trek food replicator

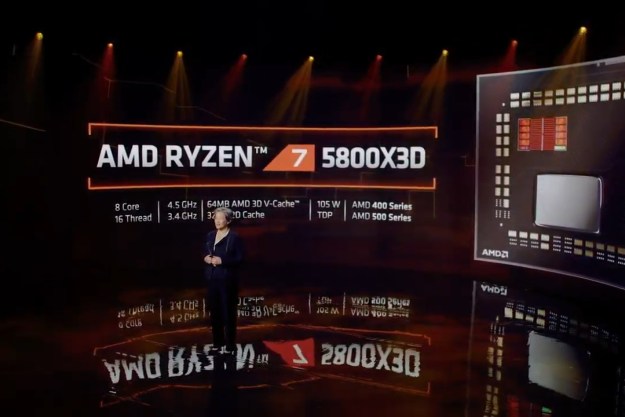

- AMD Ryzen 7 5800X3D beats predecessor, but AMD promised more

- AMD’s revolutionary 3D V-Cache chip could launch very soon

- AMD teases performance of its revolutionary 3D V-cache chip