However, it’s also expensive — and one main reason is the fact that it has to be spun by silkworms, which produce the material for protective cocoons during their pupal stage. In all, it takes upwards of 3,000 silkworm cocoons to make just one pound of silk.

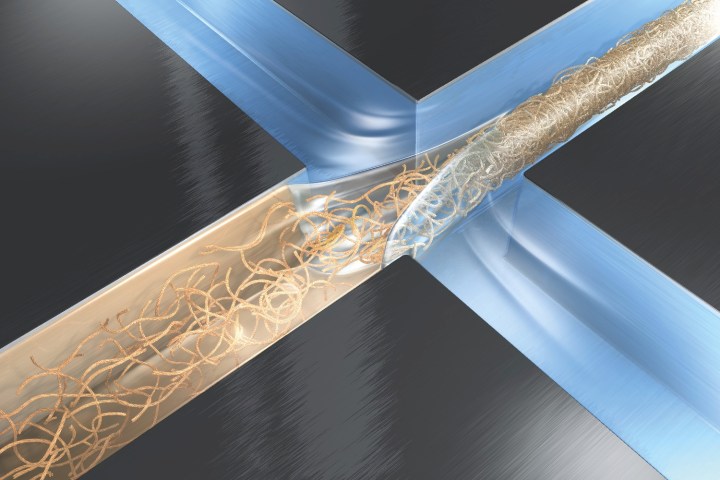

Thanks to researchers at Sweden’s Royal Institute of Technology (KTH), however, there may now be a better way. What they’ve developed is a process for artificially producing silk by adding heat and acid to a solution of whey derived from cow’s milk. This results in the formation of miniature strands of a protein called nanofibrils. Using another process called hydrodynamic focusing, in which a carrier liquid containing the nanofibrils is pumped through a tube, these nanofibrils are squeezed together to form a silk-like fiber.

“We exploit the ability of protein molecules to self-assemble into nanofibrils as a way to obtain ordered structure on the nanoscale,” Dr. Christofer Lendel, one of the two lead investigators, told Digital Trends. “To our knowledge, this is the first time someone managed to assemble protein nanofibrils into larger fibers.”

Depending on the protein concentration in the solution, these fibrils can be made shorter and thinner — which actually turns out to create a material that is stronger than one made by longer, thicker fibrils. Using X-ray technology, Dr. Lendel and colleague Dr. Fredrik Lundell from the Royal Institute of Technology in Stockholm were able to discover why this is. It’s because shorter nanofibrils are curved, thereby allowing them to lock together more effectively.

At present, the researchers have only produced artificial silk fibers of roughly 5mm. But once optimized it is hoped that this could lead to large-scale production of silk-like material. Dr. Lendel also said that nanofibrils have potential application in other biomaterials, as well as in the design of biosensors. “The opportunity to create macroscopic functionalized structures would open new possibilities in many fields,” he said.

Lendel stressed that the current study is a proof of principle, although it could lead to great things in the future.

“We now know that it is possible to make the protein fibers and we found out a few ‘tricks’ that are necessary to use,” he explained. “The next steps involve increasing the strength of the fiber, [applying] the method to protein nanofibrils from other raw materials, and to explore functionalization.”

We guess the old adage is true: where there’s a will there’s a … whey.