For the past three years, the Dutch 3D-printing company MX3D has been working to build what is possibly the world’s coolest steel footbridge. Designed to stretch across Amsterdam’s Oudezijds Achterburgwal canal, the quasi-organic-looking footbridge looks like something H.R. Giger would’ve created had he pursued a career in civil engineering.

Aside from its look, what makes the bridge exciting is its method of construction — which involved four special welding robots capable of laying down layers of molten metal.

“We use industrial robots that are commonly used in the car industry and fit them with high-end MIG-welding equipment,” Tim Geurtjens, co-founder of MX3D, told Digital Trends. “What turns that combination into a 3D printer is the software and strategies we have developed for driving the robot, and for getting a grip on the very complex welding process. Simply explained, we melt a thin wire of just about any metal you would like and deposit that upon the last layer. This way the part keeps on growing. The material that it results in is strong, durable and homogenous, just about as good as the material you put in.”

Despite this superior technology, however, Geurtjens says the process wasn’t always straightforward. “This whole project has been a great challenge,” he acknowledged. “All we knew was that we wanted to print a metal bridge with the technique we, at that time, had just started developing.”

Originally, the idea was to print the bridge “live” over the canal. But this ambitious idea — which would have made for spectacular viewing for passers-by — fell by the wayside, due to permits, budget, and time constraints. As a result, the team printed the bridge in their workshop. They also had to scale down some of the wackier aspects of the design, although the finished product still looks spectacular.

“In the design process, sometimes our imagination proved to be a bit too wild for the sometimes conservative construction world,” he said. “The level of complexity that could be achieved by our printers could not be handled by the structural engineering software for instance. However, I think that the final design shows very well what the possibilities of additive manufacturing in general and our printers in particular are. These organic, optimized forms would not have been possible to print with any other technique.”

Now that the bridge is finished, the team will next put it through its paces for load-bearing, using a variety of smart sensors and 3D scanners to test for its durability. By October 2018, final tests will be carried out and the bridge can then be installed.

Editors' Recommendations

- Nvidia turns simple text prompts into game-ready 3D models

- 3D printed cheesecake? Inside the culinary quest to make a Star Trek food replicator

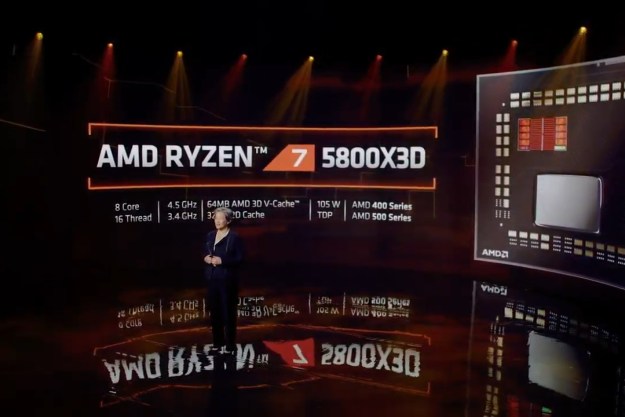

- AMD Ryzen 7 5800X3D beats predecessor, but AMD promised more

- AMD’s revolutionary 3D V-Cache chip could launch very soon

- AMD teases performance of its revolutionary 3D V-cache chip