“Our photovoltaic is about 1 micrometer thick,” says Jongho Lee, an engineer at the Gwangju Institute of Science and Technology in South Korea. For those keeping track at home, one micrometer is noticeably thinner than a human hair, and hundreds of times thinner than standard photovoltaics.

To create the ultra-thin solar cells, engineers were able to bond the cells directly onto a flexible substrate. To do this they applied pressure at a temperature of around 338 degrees Fahrenheit. The result was a “cold welding” process which created a temporary adhesive, that could later be peeled away. This helped reduce the thickness of the solar cell, compared with the standard adhesive that is used in similar photovoltaics.

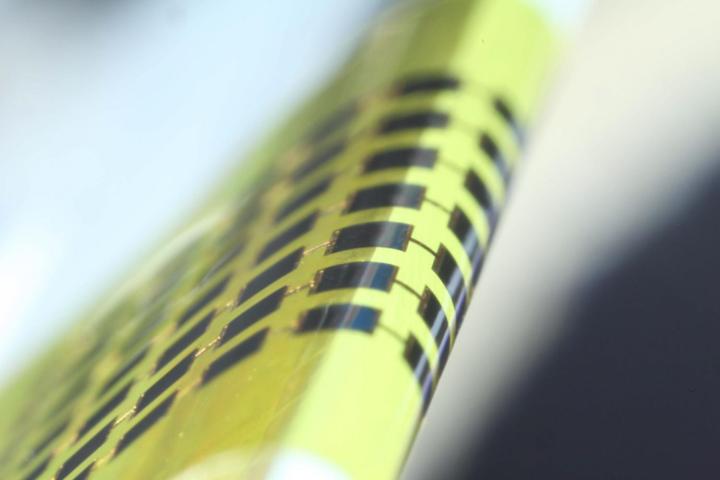

What makes this technology particularly exciting is how flexible it is. In studies, researchers discovered that the cells were capable of wrapping around a radius as tiny as 1.4 millimeters. This flexibility could make the technology well-suited for future wearable devices: a market that is rapidly growing. Whether it’s Google Glass-style smart glasses, fitness trackers like the Fitbit, or even soft fabrics for smart clothing, technologies such as this could be crucial in helping usher in the next wave of wearables.

Of course, to get there the next-gen solar technology must still undergo a variety of tests — while cautiously-excited observers will also want to see how it fares in terms of cost. “The idea of thin PV cells is not new,” Dr. Greg Wilson, Principal Research Scientist at Next Generation Photovoltaics, tells Digital Trends. “The challenge for all thin cell ideas has been to get the cost down and efficiency up so that they are competitive with incumbent cSi panels.”

Dr. Wilson notes that there while there are niche applications where thin-film cells will be valuable, ultimately it’s going to depend on cost and efficiency for innovations like this to compete directly with the major established photovoltaic technologies. If it can pass these tests with the same aplomb that it has the thickness challenge, we will be able to say for sure that we have a revolutionary new brand of photovoltaic on our hands. Keep your fingers crossed!

Editors' Recommendations

- High temperatures and a diamond anvil could lead to a solar cell breakthrough

- Amazing new glove can translate sign language into spoken words in real time

- No more panels? A.I. helps create sprayable solar cells that can be painted on

- Toyota covers a Prius in solar cells to boost its range by 27 miles