With its incredible strength and potentially miraculous applications, there is a lot to be enthusiastic about when it comes to graphene. But it’s one thing to show off these possibilities in a lab; another entirely to turn it into something that’s usable in real-world situations. That’s something that researchers from Virginia Tech University and the Lawrence Livermore National Laboratory (LLNL) have been working to change. In the process, they have found a way of combining two of the most promising buzzwords in tech — “graphene” and “3D printing” — to open up a world of new exciting possibilities.

“We have been able to achieve 3D graphene aerogels and foams with arbitrary form factors and 3D features,” Xiaoyu “Rayne” Zheng, an assistant professor with the Department of Mechanical Engineering at Virginia Tech, told Digital Trends. “We formulated and printed light-sensitive graphene precursors that is compatible with a desktop SLA printer. This opens up freedom to realize 3D graphene with any topology co-optimized mechanical properties, hierarchical pore sizes, surface areas, [and] conductivities for a host array of applications.”

Regular graphene is a single layer of carbon atoms arranged in a honeycomb-style hexagonal lattice pattern. If graphene is packed, layer on layer, it becomes graphite: A material most commonly used as the “lead” in ordinary pencils. Now we love pencils as much as the next person, but anyone who has ever had a pencil lead snap on them may have a hard time believing this is one of the strongest materials on the planet. That’s because of the way that it is packed together, which fundamentally alters the structure of graphene.

The researchers on this project circumvented that by separating the individual sheets of graphene with air-filled pores, thereby allowing it to maintain its properties. The 3D-printable material that emerges at the end is something called graphene aerogel.

“Graphene aerogels are promising for a number of applications — including energy storage and conversion, catalysis, sorbents, and desalination,” Marcus Worsley, an LLNL researcher on the project, told us. “Recent work has shown some performance improvements for simple 3D-printed structures, but more complex, computer-generated architectures are predicted to be vastly superior. These gains should translate to devices that are more powerful, efficient, and longer lasting. This is the major thrust of our current and future work in this area.”

It may be some time before we are 3D printing with graphene in our home offices, but this still represents an enormous step in that direction.

“With regards to commercialization, we are always happy to work with potential commercial partners to bring our inventions to market,” Worsley continued. A paper describing the work was recently published in the journal Materials Horizon.

Editors' Recommendations

- Nvidia turns simple text prompts into game-ready 3D models

- 3D printed cheesecake? Inside the culinary quest to make a Star Trek food replicator

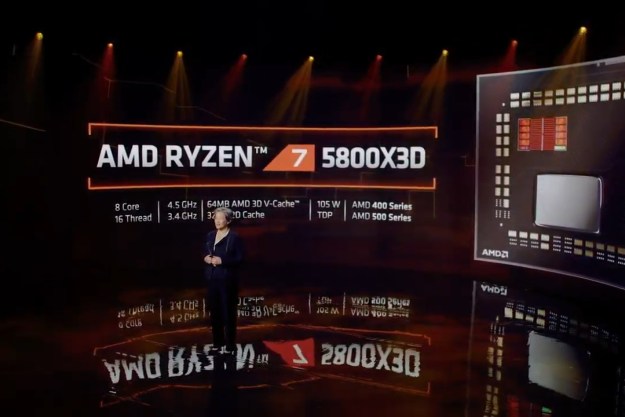

- AMD Ryzen 7 5800X3D beats predecessor, but AMD promised more

- AMD’s revolutionary 3D V-Cache chip could launch very soon

- AMD teases performance of its revolutionary 3D V-cache chip