3D printing may be more commonly associated with things like rapid prototyping for industry and homemade “maker” projects, but it also opens up some exciting medical possibilities. Chief among these is the dream of 3D bioprinting, which could one day prove useful for everything from printing small-scale fabricated tissues to the eventual goal of fully functional transplant organs.

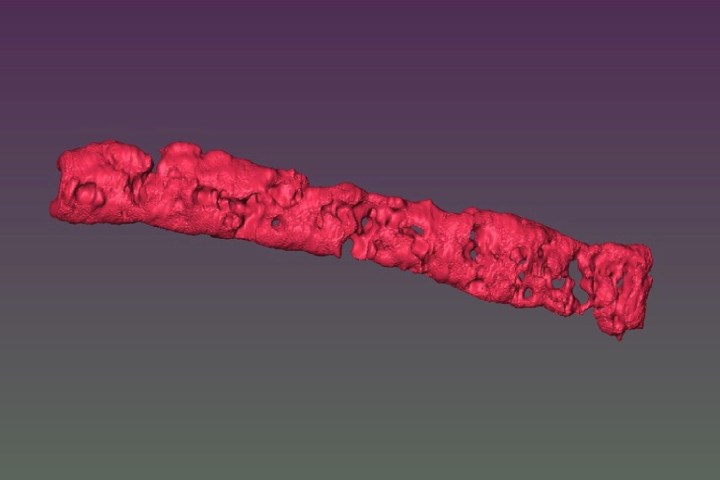

While the second of these ambitions is still a way off, researchers at Pennsylvania State University have made a big advance in the goal of creating lab-made tissues such as bone and cartilage. Specifically, they have developed a method of fabricating porous tissues, in which micro-pores allow nutrients and oxygen to circulate, thereby keeping the cells healthy.

The process involves taking human stem cells and mixing them with a sodium alginate material derived from seaweed. This can be printed into particles which, once dissolved, leaves tiny breathable pores. Combined into strands it is possible to create patches of tissue. The undifferentiated stem cells are used to convert the tissue into specific cells, such as bone or cartilage. The team who worked on the project are also looking at how this same technique could be used to create muscle, fat, and an assortment of other tissues.

“These patches can be implanted in bone or cartilage, depending on which cells they are,” Ibrahim Ozbolat, associate professor of engineering science and mechanics at Penn State, said in a statement. “They can be used for osteoarthritis, patches for plastic surgery such as the cartilage in the nasal septum, knee restoration, and other bone or cartilage defects.”

But as promising as the work is, there is still more that needs to be done. That is because, as of now, it is only possible to make tiny patches of the material, thereby limiting its usefulness. However, these patches — while small — are reportedly considerably easier to fabricate than alternate methods, such as growing artificial tissue on scaffolding. If the researchers are able to develop the approach to make larger-scale printing possible, this latest innovation could turn out to be a considerable step forward in the field of 3D bioprinting.

Editors' Recommendations

- Nvidia turns simple text prompts into game-ready 3D models

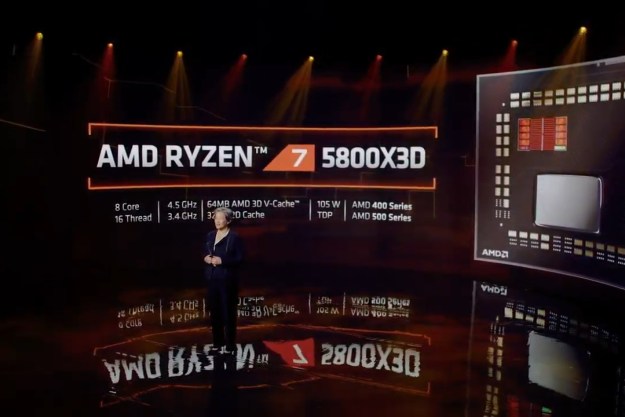

- AMD is bringing 3D V-Cache back to Ryzen 7000 — but there’s a twist

- AMD Ryzen 7 5800X3D details leak, and there’s some bad news

- AMD teases performance of its revolutionary 3D V-cache chip

- Fighting football injuries with 3D-printed, hyper-personalized pads