There are few things more annoying than spending hours in your local furniture store, finally picking out the DVD cupboard that best sums you up as an individual — only to get home and find that it doesn’t fit the space you had planned to put it.

That’s where a nifty new design concept, created by Netherlands-based designers Jesse Kirschner and Jesse Howard, comes in. Called Standard Products, it’s a fresh take on furniture for the digital generation, based around user customization.

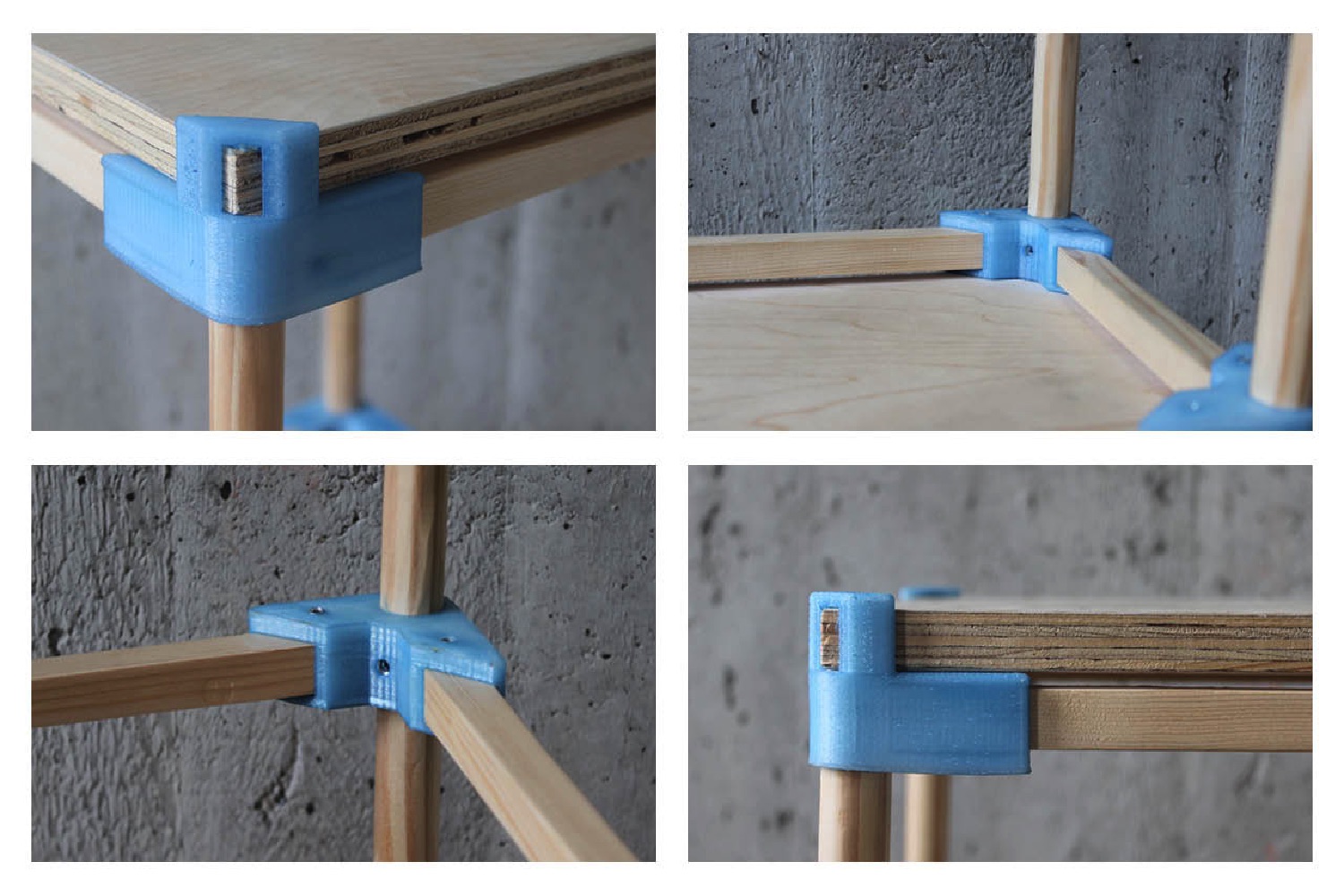

In short, users choose the product they want (say, a new shelving unit), then use a web-based interface to adjust the physical dimensions of the product, select the materials that will be used to build it, and then generate the needed 3D-printable components to hold it together.

“What we’re looking to create is an online platform where people have the opportunity to look at the digital design of a piece of furniture, and then modify it to their needs,” Jesse Howard told Digital Trends. “That could be changing the width to fit a specific alcove in their house, or changing the height to make a stool the perfect height for them. It also gives people the chance to adjust to use whatever materials they have available at their local hardware store.”

Over the past year, Kirschner and Howard have developed a collection of objects in this vein. At present, they’re raising money on Kickstarter to evolve the concept into a comprehensive platform that will make the customization process available to everyone. As rewards, people pledging money to the campaign can buy the digital files for their choice of a standard cupboard or a stool. Prices start at 10 euros ($11.)

“This very much comes into the sphere of flat-pack furniture,” Jesse Kirschner told us. “What is interesting, though is that it can also enter the world of bespoke furniture by choosing more high-end materials. Rather than selecting pine as your wood, you might go with something more expensive instead. This part of the process is very interesting to me.”

They also hope that this digital distribution method might help cut down on the carbon footprint of furniture, since the 3D-printed components and building materials can be sourced locally, as opposed to being shipped large distances.

So what does this mean for the future of designers, who are often used to having the final say over how their products look?

“We view it as a collaboration,” Kirschner said. “We even want to open up the code, so there’s a co-creatorship of the object itself. Customers can make it bigger, smaller, use the internal structure for something else entirely — whatever they want. We believe in this idea, where designers won’t design the final object but rather design the meta object. However, in terms of its specific form, the end user is the one who decides what he or she wants.”

Editors' Recommendations

- Nvidia turns simple text prompts into game-ready 3D models

- AMD is bringing 3D V-Cache back to Ryzen 7000 — but there’s a twist

- AMD’s revolutionary 3D V-Cache chip could launch very soon

- Fighting football injuries with 3D-printed, hyper-personalized pads

- AMD’s 3D-stacked Ryzen 7 5800X3D is ‘world’s fastest gaming processor’