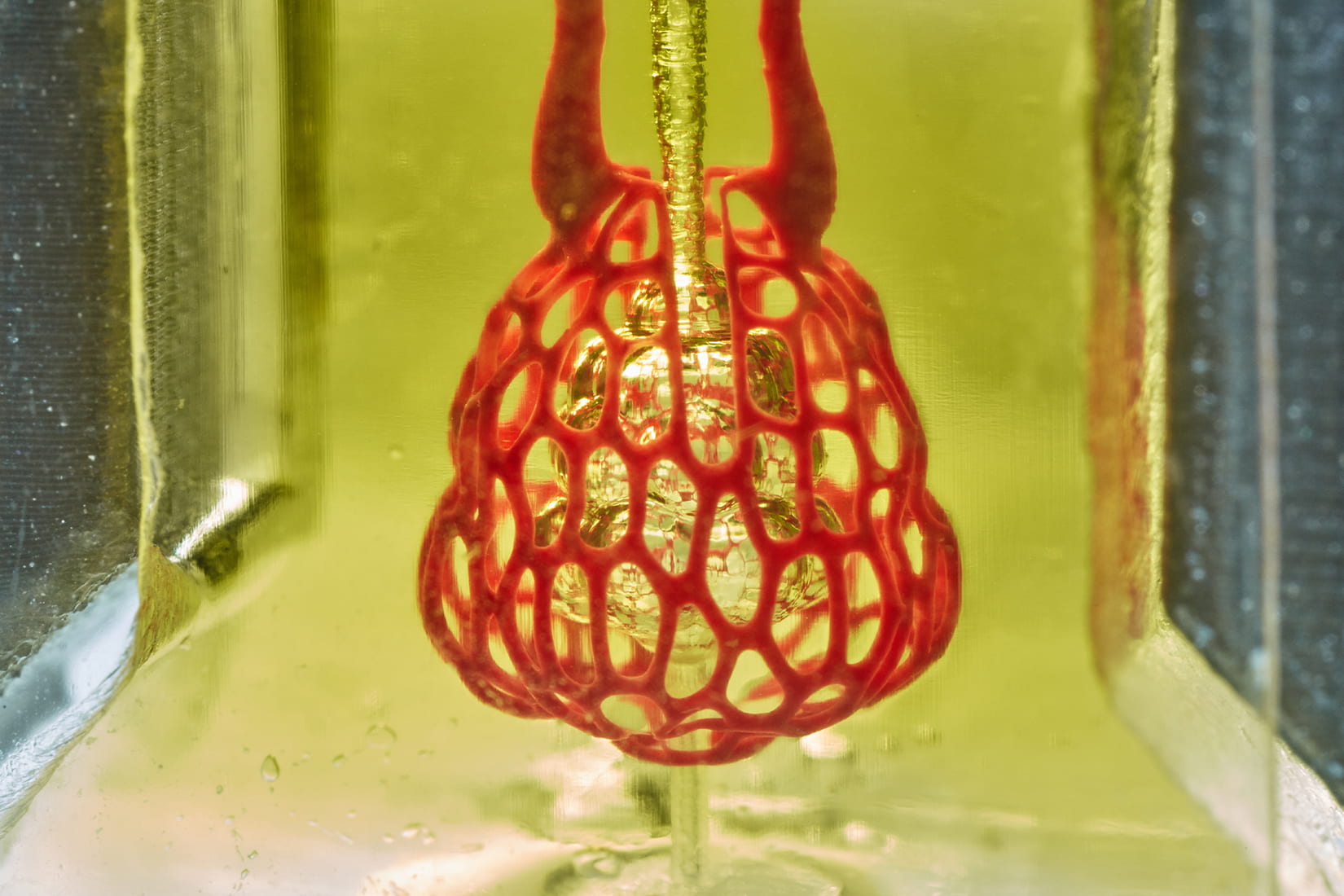

Scientists have taken a major step towards the 3D-printing of replacement organs. A new technique for bioprinting tissues allows scientists to create vascular networks like those used in the body to transport blood, air, and other fluids.

Along with publishing the research in the journal Science, the scientists released a video showing a lung-like air sac which can feed nutrients and oxygen to nearby tissue:

“One of the biggest road blocks to generating functional tissue replacements has been our inability to print the complex vasculature that can supply nutrients to densely populated tissues,” Jordan Miller, assistant professor of bioengineering at Rice University’s Brown School of Engineering, explained in a statement.

“Further, our organs actually contain independent vascular networks — like the airways and blood vessels of the lung or the bile ducts and blood vessels in the liver. These interpenetrating networks are physically and biochemically entangled, and the architecture itself is intimately related to tissue function. Ours is the first bioprinting technology that addresses the challenge of multivascularization in a direct and comprehensive way.”

The importance of this development was underscored by Miller’s colleague, Kelly Stevens of the University of Washington. “Tissue engineering has struggled with this for a generation,” Stevens said. “With this work we can now better ask, ‘If we can print tissues that look and now even breathe more like the healthy tissues in our bodies, will they also then functionally behave more like those tissues?’ This is an important question, because how well a bioprinted tissue functions will affect how successful it will be as a therapy.”

The scientists expect that bioprinting will become a part of mainstream medicine with the next 20 years. Current research is being performed in both university and private settings, such as startup company Volumetric which employs several of the researchers. But Miller is a proponent of open-source 3D printing and has made all the data from this experiment freely available through the publication in the journal Science.

Editors' Recommendations

- 3D printed cheesecake? Inside the culinary quest to make a Star Trek food replicator

- AMD’s revolutionary 3D V-Cache chip could launch very soon

- Fighting football injuries with 3D-printed, hyper-personalized pads

- Need a last-minute Halloween costume? Check out these 3D-printable getups

- NASA is testing a 3D printer that uses moon dust to print in space