“Here at the Center for Additive Manufacturing, we’re exploring ways of developing additive manufacturing beyond single material deposition to the ability to manufacture a working system straight out of the machine,” Professor Chris Tuck, professor of materials engineering and lead investigator of the study, told Digital Trends.

The researchers’ new approach involves printing circuits made of electrically conductive metallic inks and insulating polymeric inks. These can be produced in a single inkjet printing process, using an ultraviolet light to solidify the inks. This solidification process takes less than one minute per layer, which is far quicker than other approaches that made it impractical to consider printing objects with hundreds of different layers.

The approach also allows for the printing of multiple materials in one object. The researchers hope that this will make it possible to print more ambitious electronic items in the future — for example, a wristband with both pressure sensor and wireless communication circuitry.

“This means we can begin to explore producing three-dimensional circuits and structures in a single manufacturing step,” Tuck continued. As with 3D printing as a whole, what makes this work exciting is that engineers would be able to more easily customize each item to a certain use case.

Tuck’s colleague, engineering research fellow Ehab Saleh, told us that the team has already been approached to use the technique to work on some “exciting applications,” although the researchers are not able to reveal specifics as of yet. “The outcome of the work could enable many real-world applications in electronics where a complete device with a complex geometry could be 3D printed with a press of a button,” Saleh said.

A paper describing the work was recently published in the journal Advanced Materials Technologies.

Editors' Recommendations

- Nvidia turns simple text prompts into game-ready 3D models

- 3D printed cheesecake? Inside the culinary quest to make a Star Trek food replicator

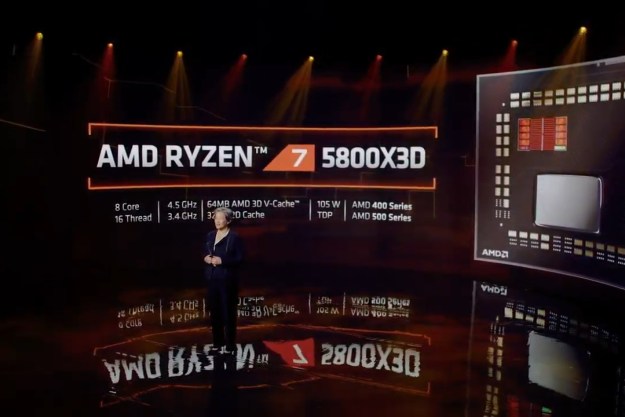

- AMD Ryzen 7 5800X3D beats predecessor, but AMD promised more

- AMD’s revolutionary 3D V-Cache chip could launch very soon

- AMD teases performance of its revolutionary 3D V-cache chip