Porsche has found a clever use for 3D printing technology. The company is experimenting with ways to produce 3D-printed seat cushions that will give buyers the option of specifying the amount of firmness they want.

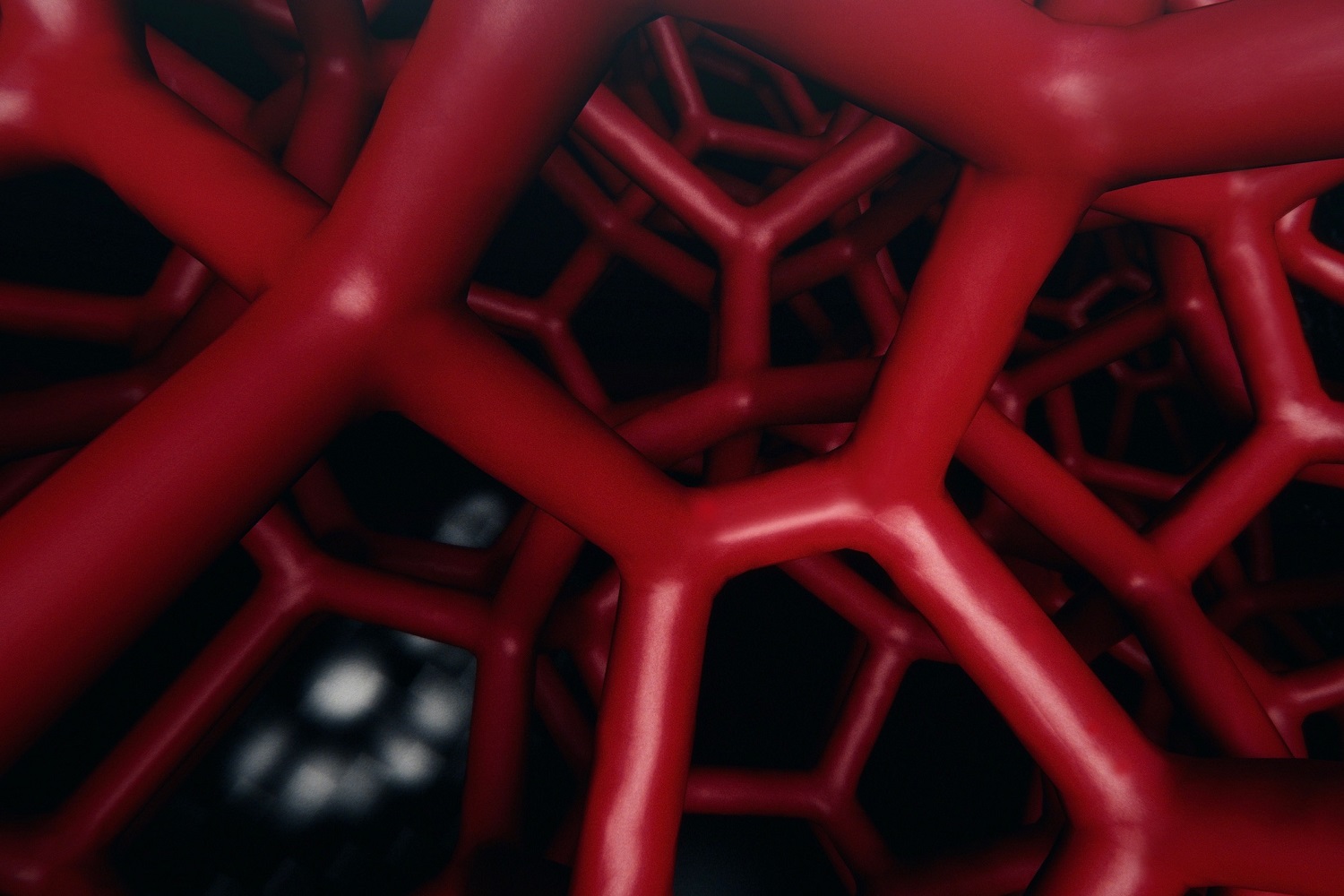

Its engineering department starts with a shell made with carbon fiber to keep weight in check. It then adds a layer of foam and tops it with a 3D-printed piece, the firmness of which depends on each buyer’s preference. Enthusiasts will initially have three firmness options to choose from (hard, medium, and soft). The chosen upholstery tops this layer.

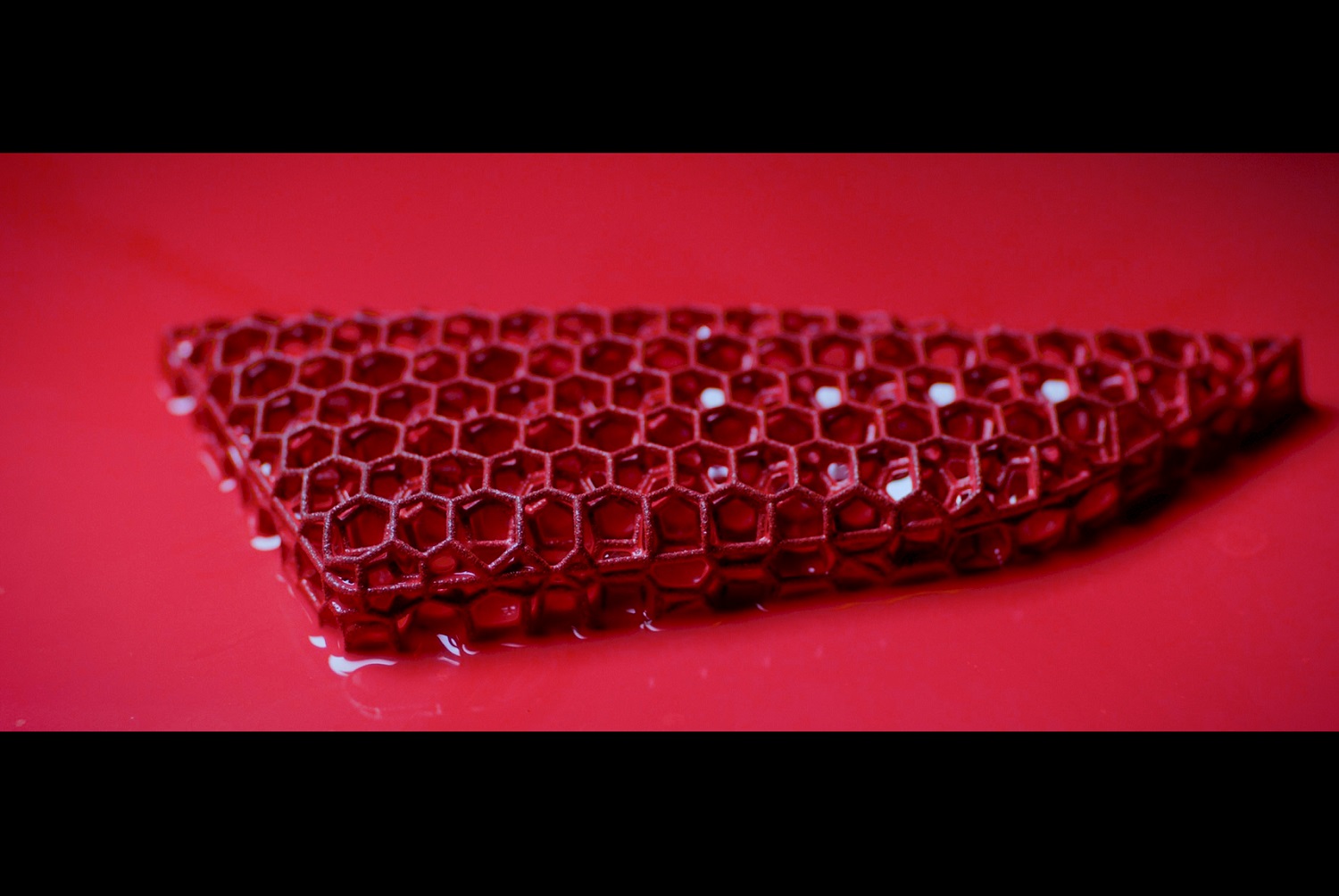

The honeycomb-shaped latticework that emerges from the 3D printer is visible on either side of the seatback, adding a touch of tech-infused coolness to the car’s cabin. Porsche explained the end result isn’t only about looks or comfort; the bucket seat is actually lighter when built using this technique than units it currently puts in its cars, and it’s more comfortable to sit on daily. It can be cooled or heated, too, so you won’t sweat or freeze.

Looking ahead, and if buyer demand is there, Porsche expects advancements in 3D printing technology will help it work with individual customers to create a custom-designed seat from scratch. Buyers will have the option of selecting the level of firmness and support they want, whether they need it heated or cooled, and its color. They might also have the option of letting someone at Porsche measure their body to develop a seat.

Porsche will begin making 3D-printed seat cushions for the 911 and the 718 in May 2020. It will initially cap production at 40 prototype units that will end up underneath the butts of European race car drivers. The feedback the company receives from these early adopters will help it improve the technology, and the cushions will join the long list of Porsche Exclusive Manufaktur options halfway through 2021. Pricing hasn’t been announced yet, but don’t expect this option to become a budget-friendly alternative to standard, one-size-fits-all seat cushions.

The idea of offering à la carte seats, Subway-style, isn’t new. The odds of you fitting in the 919 Hybrid that won the 2017 edition of the 24 Hours of Le Mans are spectacularly low because, like a majority of high-level race cars, it’s fitted with a seat tailored to the person designated to drive it. Porsche swapped seats at every driver change. This practice is rare in the lower echelons of the automotive industry because it’s costly, though Aston Martin is measuring the patootie of every person who buys a limited-edition Valkyrie hypercar so it can manufacture custom seats.

Editors' Recommendations

- Los Angeles-based Czinger is 3D-printing a 1,232-hp hybrid hypercar

- This 3D-printed electric car could be sketchiest Kickstarter yet

- Volkswagen and HP want your next car to have 3D-printed parts

- Flat-six makes a brief but triumphant return in Porsche’s hot-rodded 718 duo