Nothing makes autonomous driving news like an overblown disaster, but the really important developments in self-driving cars rarely get any attention. Proof of this phenomenon is that almost nobody has heard about the AutoDrive Challenge sponsored by General Motors and the Society of Automotive Engineers.

This challenge is a three-year program involving teams of mechanical engineering students from eight different colleges across America. Each year, the students are tasked with developing technology to meet an increasingly sophisticated set of autonomous performance targets, using a 2017 Chevrolet Bolt (provided by GM) as the development platform. The final goal of the competition is to successfully navigate an urban driving course in level four automated driving mode.

The teams recently completed the first year of competition. They traveled to GM’s proving grounds in Yuma, Arizona, to offer presentations on their understanding of the fundamentals of autonomous driving and demonstrate that their tech could drive the car on a closed test track, displaying proficiency in object detection and avoidance, mapping, and lateral lane management.

Digital Trends recently sat down with the third-place team, Victor Tango AutoDrive from Virginia Tech, to find out how its members approached the challenge and what obstacles they had to overcome to succeed. While it placed third in most phases of the competition, Victor Tango stood out as the only team that successfully completed the lateral lane management exercise.

Team Building

Bhavjot Michera is a mechanical engineering student at Virginia Tech, and a team member of Victor Tango.

“We were basically given a Chevy Bolt from General Motors, and with the help of some graduate assistants and our lead faculty advisor, Dr. Wakes, we embarked on this project for the year,” Michera said.

Michera’s primary role on the team is hardware engineering, but he was also involved in team building.

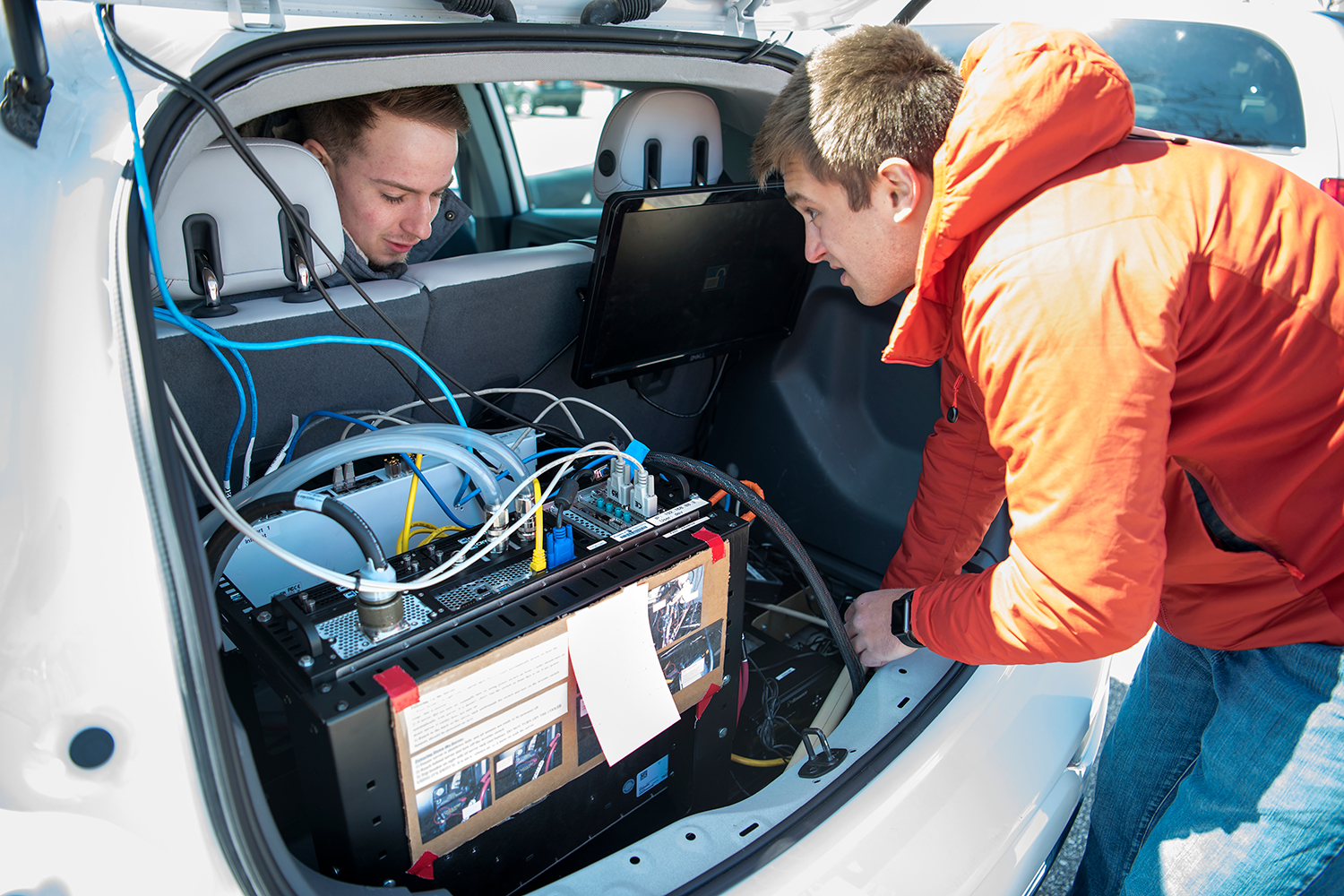

“It was our team’s responsibility to be able to securely and efficiently mount all the components that we were using,” Michera told Digital Trends, “such as the cameras, lidar and radar, and the GPS systems. We had to mount them to the specifications that our other sub-teams asked for. The cameras had to be able to see a full view angle, just like our radars and lidars. We also ensured that all the connections, the wiring for the entire vehicle were done and installed.”

“We go out to the local high schools and show the project to find students who are interested in coming into this field.”

“I was also part of the outreach team,” Michera added. “We interviewed potential members to join the team, because each year seniors will graduate so we have to bring on more members. We’ve been recruiting other members from Virginia Tech to join our team and we go out to the local high schools and show the project to find students who are interested in coming into this field. We bring them in and give them a tour of our garage and show them how the vehicle works. We’ve worked with other high school robotics programs to grow interest in this field.”

The Long Road to Yuma

Before it could go to Yuma, the team had to develop and test its own integrated autonomous driving system. As any automaker’s autonomous team could tell you, it’s not easy. In the final weeks before the deadline for demonstrations, the team suffered two major setbacks.

“The project has gone really well,” Michera insisted, “but it’s funny because we did have a small hiccup. Due to human error, the vehicle actually crashed into the garage door where we were working.”

The team had to double down and make sure the car could be fixed before the competition.

“We were so lucky that none of the major expensive components like the cameras and lidars were damaged,” Michera said. “There was only small cosmetic damage to the vehicle. What I loved seeing was with that setback, the team did not lose morale in itself. We all accepted it, that it’s a small mistake, and kept going with the same attitude towards finishing this goal.”

Murphy wasn’t quite done with the Victor Tango team, however.

“We were given the vehicle back with nine days left. And you best believe that we made it.”

“Unfortunately, we met with another obstacle,” Michera continued. “Our vehicle failed to charge, and that was an issue that we couldn’t fix. We sent the car to the dealership, and they couldn’t diagnose it, and so we had to send it all the way to General Motors in Michigan. We were without the vehicle for almost a month, so we lost all that time to do our testing.”

With no vehicle to develop and no idea when it would return, the team considered throwing in the towel. When the Bolt was fixed and got back to Virginia, the team had only a little more than a week to do a month’s worth of work.

“We were given the vehicle back with nine days left. And you best believe that we made it. Most of the team was working day in and day out. I’ve seen multiple 3:00 AM mornings there, making sure that we completed all the testing procedures to have a safe vehicle. That was one of the main objectives. Our faculty advisor said that he didn’t really care if vehicle looks absolutely great cosmetically. We wanted to ensure that the systems and everything integral to the functioning of the vehicle worked flawlessly. We were able to get the car ready and everything set to go within nine days, and we were able to compete.”

The Big Challenge

When the team got to Yuma, there were reports to deliver and technology to be demonstrated.

“We had social responsibility reports explaining the design, why we chose to have the design we did. What components we used in our design,” Michera said. “We had to justify the reasons why we used those components and state their advantages and disadvantages.”

Giving a report is one thing. Making a car that drives itself on a test track is a bigger deal.

“The challenge of this year was stationary objects,” Michera explained. “Not only did we have stationary objects, we had to do obstacle avoidance, and we had to do lane following, and general control of the vehicle.”

When the time came for the actual demonstration, it turned out that the Victor Tango team’s misfortunes had actually helped them. Due to the reduced time available, the team was forced to use a fusion of methods to integrate traditional environment mapping with the complex perception algorithms used by the cameras and lidar systems.

“Everyone else at the competition hadn’t relied on the maps because they figured they could do it entirely with perception,” pointed out team member Andy Cohen. “But the environment wasn’t as well regulated as they thought it was going to be.”

It turned out that the lane lines at the proving grounds were faded, as they are on many roads throughout the world. Because their vehicle could navigate the track without relying on the camera identifying the lane lines, Victor Tango AutoDrive was the only team that was able to complete the lateral movement challenge.

“I think that, even though we didn’t take the first-place trophy, in our hearts the fact that we were able to get the vehicle done and able to finish all three challenges when no other college was able to do that made this a huge, huge win in our books,” Michera beamed. “I think it just goes to show about the motivation for this team and what’s in store for the next couple of years as well.”

The Road Ahead

Because the competition will take place over three years, each team will graduate at least two cohorts of seniors, with younger students coming up to take their places and continue the challenge.

“I plan to use it as my senior design project and hopefully take it all the way through the three years,” Michera said. “I’ve always been a very big aficionado of cars and everything to do with them. I’m also aware of how the market’s moving toward autonomous. I feel like this project will give me a strong edge to actually work in the industry.”

You can follow the AutoDrive Challenge for the next two years at http://www.autodrivechallenge.com.

Editors' Recommendations

- Apple’s rumored car could cost the same as a Tesla Model S

- Watch San Franciscans take a ride in Waymo’s self-driving car

- MIT’s shadow-watching tech could let autonomous cars see around corners