Outside of tattoo conventions, few people would honestly say that they enjoy getting stuck with needles. As a result, researchers have been hard at work to develop alternatives — ranging from combining all our shots into one long-lasting injection to a needle-free device which blasts drugs into the body at Mach 0.7. New research coming out of the University of Texas at Dallas adds another pain-saving option to the list: A 3D-printed dissolving microneedle array, which could offer a far less daunting alternative for the needle-phobic among us.

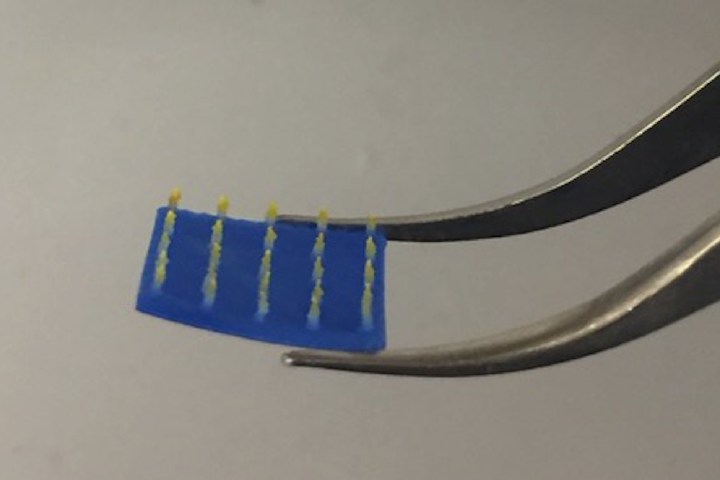

“Microneedles are very tiny needles that can deliver drugs and vaccines into the body through the skin,” Jeremiah Gassensmith, assistant professor of Chemistry and Biochemistry, told Digital Trends. “They’re very small, so they don’t hurt, which makes them desirable as a way to replace traditional syringes. We are interested in making them out of materials that get embedded in the skin and dissolve over time releasing drugs or vaccines slowly.”

Usually producing microneedles would require specialized equipment in the form of a cleanroom. The issue is that this is not something that many smaller companies have access to. “We basically found a way to cut out the multimillion-dollar clean room with a $1,000 Lulzbot,” Gassensmith explained. “We print microneedles, do some post-print processing on them to make them super-sharp, and then we show we can load small molecules into them and release them into the skin over time.”

So far, the microneedles have been tested on pig skin, where they were shown to be capable of delivering a sample dose of dye molecules beneath the skin, similar to how a drug might be delivered in the body. By applying a slight sideways force, more than 80 percent of the needles break off in the skin. They then deliver their drug payload over time as the needles dissolve — due to being made of the non-toxic polymer polylactide, the same material already used in dissolvable stitches.

“We’d love to get plastic filaments that are loaded with specific drugs that are typically only effective when administered by IV,” Gassensmith said. “Instead of getting multiple shots, your doctor would print out a therapeutic microneedle patch and mail it to you and you could apply it yourself at home. One of the great advantages of microneedles is you don’t need to be trained to use them. They’d be great for deployment where formulating IV drugs would be a hassle, like in delivering vaccines to developing countries. The 3D-printing technology is ready to be commercialized right now, and we are actively working on finding candidate drugs to use for our spools.”

Editors' Recommendations

- 3D printed cheesecake? Inside the culinary quest to make a Star Trek food replicator

- Fighting football injuries with 3D-printed, hyper-personalized pads

- NASA is testing a 3D printer that uses moon dust to print in space

- The best 3D printers under $500

- Hit takers: The cutting-edge engineering making football helmets safer than ever