We don’t necessarily think of inspection tasks as being particularly dangerous. But that’s probably because most of us have never had to do them. While there are certainly inspection jobs that amount to little more than form-filling and box-checking, there are others that require daredevil feats such as climbing to dizzying heights, braving high temperatures, or otherwise risking life and limb by entering inhospitable environments. Fortunately, drones are here to help.

A Norwegian startup called ScoutDI (the DI stands for Drone Inspection) has developed unmanned aerial vehicles (UAVs) for one of these seemingly mundane, but actually surprisingly challenging, inspection tasks. The challenge: To inspect the liquid-conveying tanks used on tanker ships for potentially damaging cracks. On paper, that might sound easy. Not so.

“Using current methods, you would require either scaffolding or rope access to reach all areas of the structure which could be upwards of 30 meters (100 feet) high,” Christopher Skinner, VP Sales and Business Development at ScoutDI, told Digital Trends. “This operation can be risky for the personnel involved during both the preparation and inspections activities, due to the risk of falling accidents.”

It’s not just the height that’s dangerous, either. The internal atmosphere of these tanks can be a cause for concern due to oxygen shortage or harmful gases, while the temperatures can prove … uncomfortable for flesh-and-blood inspectors.

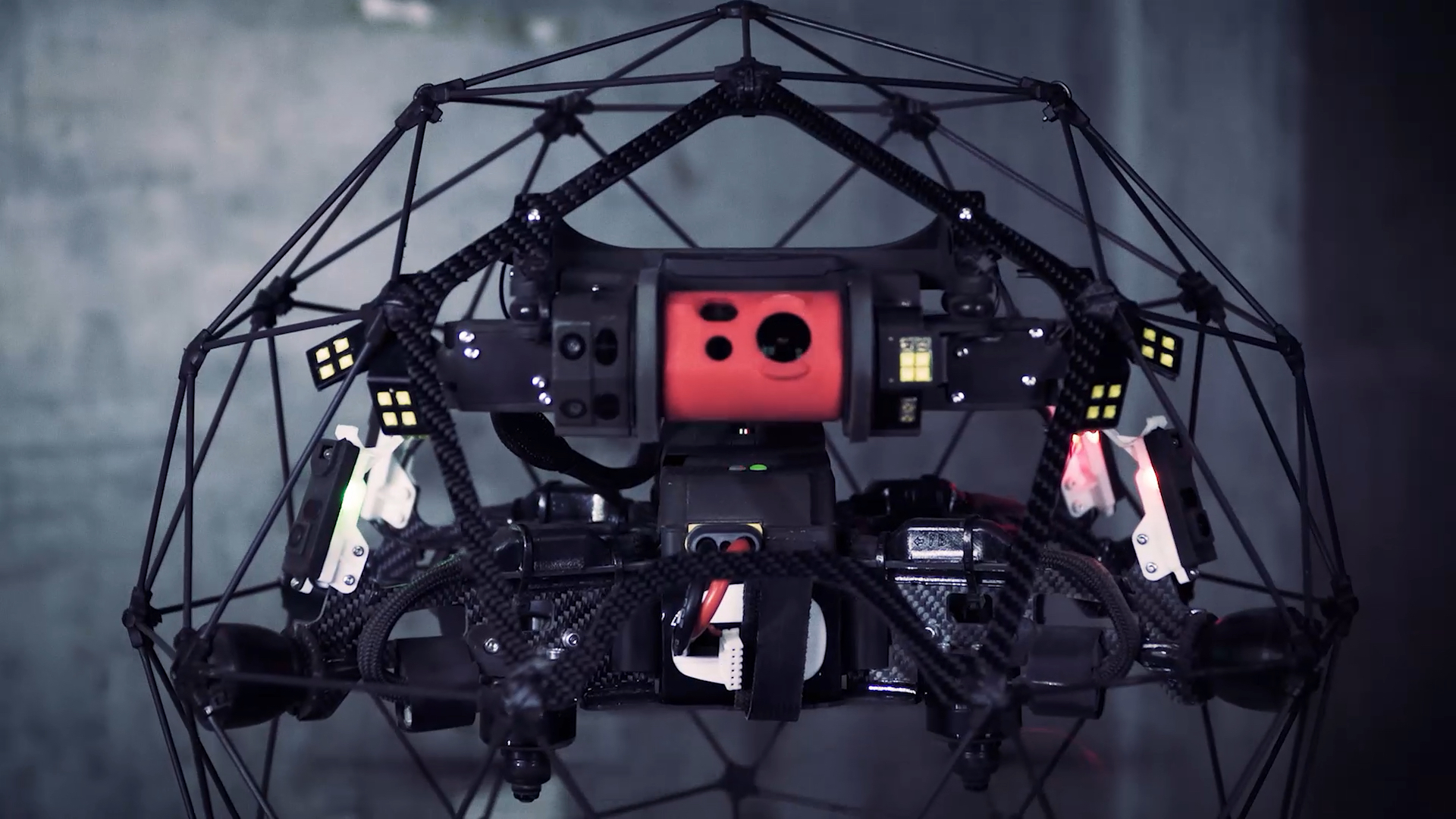

ScoutDI’s Lidar-equipped Scout 137 drone system means humans never have to put themselves in these potentially hazardous environments. The drone is specially designed to fly in confined spaces with limited entry and exit points. “Confined space inspection often requires people to enter these environments which can be both a hazardous and expensive exercise,” Skinner said.

Mapping surroundings

Once it has entered a hazardous environment, the drone uses its advanced laser sensors to build a 3D map of its surroundings. It then carries out its inspection — using onboard 4K cameras, alongside 3D tagging on an associated map — to be able to spot potential problems that may need to be the subject of maintenance. The drone is a tethered system, meaning that it can stay in the air and operate for as long as is needed. “Your flight time and the continuity of the inspection data is not limited or broken up by the need to swap batteries or recharge,” Skinner said.

The Scout 137 drone is already being used by customers in Norway, Singapore, and Indonesia, and a full product launch is coming later this year.

“While the system is currently flown by a pilot, we are continuing to add navigational and flight control aids to reduce the pilot stress and improve the safety of the flight operations,” said Skinner. “Eventually, our goal is to develop complete automated solutions that can be deployed flexibly and quickly.”

This is far from the only example of inspection drones being used in some seriously tough environments. When researchers wanted to explore the world’s deepest ice caves, close to 1,000 feet below ground level on the Greenland ice sheet, they turned to inspection drones made by the Swiss company Flyability to carry out the task. When the company isn’t being called in to help explore subterranean ice caves straight out of a sci-fi horror movie, its Elios 2 drones are used for visual assessment tasks in a bevy of scenarios in which there are confined spaces pose a challenge for human inspectors. That might be a grain silo, a septic tank, an underground mine, sewer, storm drain, manure pit, or crawl space. Basically, any place you don’t want to have to send a person — or doing so may prove tricky — Flyability’s drones can help.

According to the Bureau of Labor Statistics, 1,030 people died in the United States between 2011 and 2018 as a result of occupational injuries involving confined spaces. Add to that the 4,500 people injured and 60 killed each year due to scaffold-related accidents, and it becomes clear how valuable drones can be in this space.

“The use of drones for inspections, both internal and external, has been growing every year,” Zacc Dukowitz, a marketing manager at Flyability, told Digital Trends. “We are also seeing more and more use cases arise all the time, indicating a growing interest in and adoption of drone technology for inspections.”

A task ripe for automation

In Andrew McAfee and Erik Brynjolfsson’s book Machine Platform Crowd, the two MIT Sloan School of Management researchers classify the work robots should ideally be doing as dull, dirty, dangerous, and dear (meaning expensive). Drone inspection is a great example of this. Much of the narrative around automation is, rightly, focused on the impact it could have on humans. After all, there’s something inescapably threatening about an automated process that promises to do your job faster and more cheaply than you can — and to do it 24/7, with none of those pesky requests about weekends off or the need to sleep at night.

But scenarios like these ones show where automation can be beneficial. With jobs like this carried out by drones, humans will be freed up to focus on more valuable, less dangerous and dirty, tasks. When it comes to monitoring infrastructure, that could translate to saving lives — whether it’s the lives of those who would have been carrying out the inspections or of those who could be injured (or worse) by the failing of that infrastructure. This is one area where we should be more than willing to welcome our new drone overlords.

Editors' Recommendations

- DJI Mini Pro 4 leak appears to reveal the drone’s specs

- DJI’s 2022 drone contest offers record prize pool

- Is DJI about to release a new drone?

- Watch this Mavic 3 drone soar above the world’s highest mountain

- DJI’s latest Mavic 3 update made me love the drone all over again