And then there are the times when it’s used to print out fully-automatic gatling guns capable of firing off 48 rubber bands in a matter of seconds. Is it wrong that part of us isn’t sure which of these three is our favorite application?

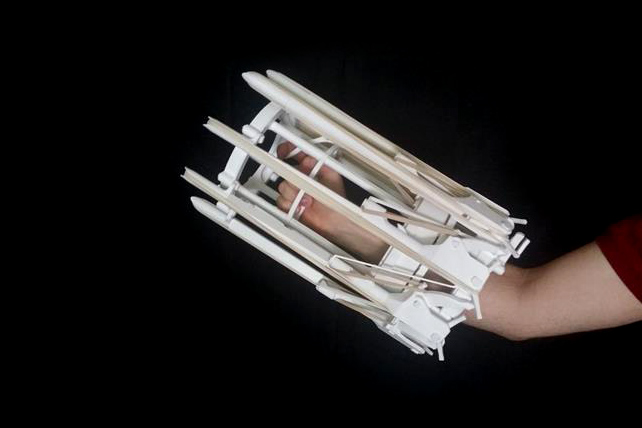

Created by 3D printing artisan Matthew Davis, the so-called “Arcus” is a thing of beauty, and snaps together without the need for screws or glue. Davis has made the instructions available over at Instructables, although you’ll need plenty of time and patience to get all of your 3D printed parts ready for assembly.

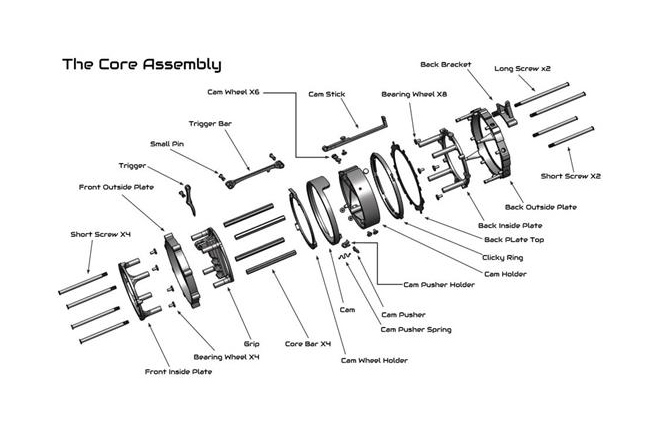

“I’d seen a 3D printed rubber band gun online before, which was just a basic hand-held one. I thought it was really cool, so I just set out to design my own,” Davis tells Digital Trends. “The hardest part was making it strong enough to hold the elastic bands, and getting the spinning mechanism to work was a real challenge too.”

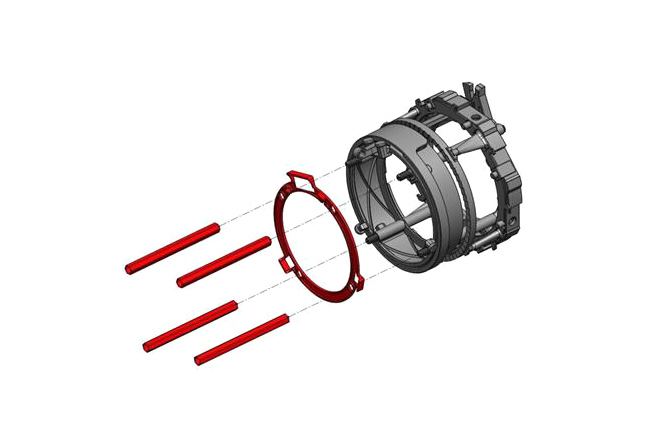

As Davis notes, the Arcus isn’t the first 3D printed rubber band gun to show up online, but it’s definitely got some nifty features. “Unlike almost all of the other rubber band Gatling guns out there, the Arcus uses the energy from the rubber bands that it is shooting to spin the barrels,” he explains in accompanying notes. “The Arcus also features the arm mount system, meaning that to hold it you put your arm through the center and the barrels will spin around your arm. A cam system is used so that when you pull the trigger the barrels will start the rotation.”

If you’ve ever wanted to know what Final Fantasy’s Barret Wallace would print if he ever got his hands (err, hand) on a 3D printer, look no further!

Did we mention how much we love additive manufacturing?

Editors' Recommendations

- 3D printed cheesecake? Inside the culinary quest to make a Star Trek food replicator

- AMD’s revolutionary 3D V-Cache chip could launch very soon

- Fighting football injuries with 3D-printed, hyper-personalized pads

- Need a last-minute Halloween costume? Check out these 3D-printable getups

- NASA is testing a 3D printer that uses moon dust to print in space