That’s according to a new project by renewable materials specialist American Process Inc. in association with Swansea University Medical School in the U.K. Researchers on the project are developing durable 3D-printed tissue that’s capable of being used in a variety of ways as part of facial reconstruction.

“We are printing living tissues, living structures, tailored to the needs of individual patients,” project lead Professor Iain Whitaker has said. “We hope that in the future, patients who have lost all or part of their ear or nose through trauma or cancer could have reconstruction using new tissue which is grown from their own cells using nanocellulose. Biomaterials are a key component of our tissue-printing technology and nanocellulose is our biomaterial of choice because of its biocompatibility, mechanical and structural properties that can support cell attachment and growth in three dimensions.”

The “nanocellulose” that Whitaker refers to is a type of bioink, a substance made from living cells that can be printed like regular 3D printing materials. What reportedly makes nanocellulose such a promising bioink is its high water-holding capacity, as well as its composition, which takes the form of an easy-flowing gel during printing, but then hardens into a dense, smooth structure capable of keeping living cells fixed in place. Researchers on the project say that nanocellulose is “ideally suited to nozzle-based 3D bioprinting” as a result of these properties.

Unlike some of the longer-term possibilities of bioprinting — such as the ultimate dream of printing out vital biological organs — projects like this one are exciting because of what they suggest about near-term solutions. Digital Trends has recently reported on other bioink projects including a related venture that promises to 3D print cartilage and bone implants for damaged body parts.

With 3D printing also looking to become a routine part of facial reconstruction, it seems that additive manufacturing is going to keep right on playing a growing role in surgery over the years to come.

Editors' Recommendations

- Nvidia turns simple text prompts into game-ready 3D models

- 3D printed cheesecake? Inside the culinary quest to make a Star Trek food replicator

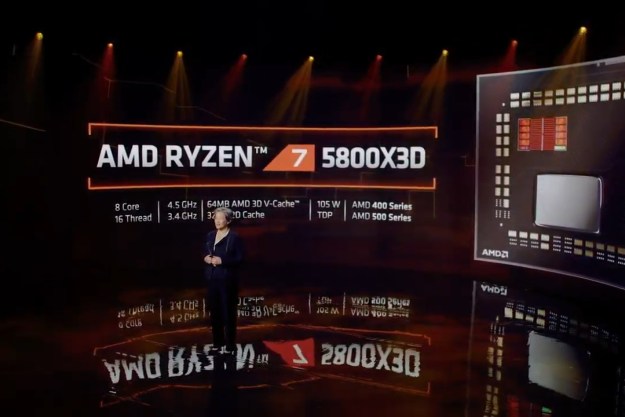

- AMD Ryzen 7 5800X3D beats predecessor, but AMD promised more

- AMD’s revolutionary 3D V-Cache chip could launch very soon

- AMD teases performance of its revolutionary 3D V-cache chip