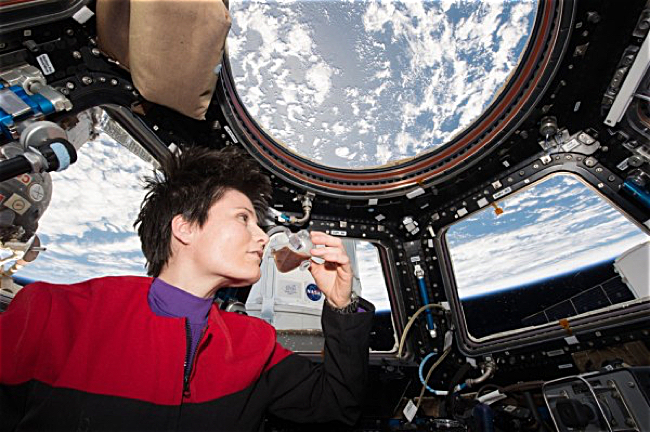

The idea for studying coffee and other liquids consumed in space surfaced after Italian European Space Agency astronaut Samantha Cristoforetti received an espresso machine. The opportunity to study capillary flow, liquid containment, and low-gravity fluid dynamics was too great to pass up. A team of researchers was assembled by NASA, and they went to work designing six different transparent polymer cups for use on the space station.

Five of the cups hold 150ml, while the sixth, a smaller 60ml vessel, was designed specifically for holding espresso. The cups were shaped with a crease to hold the drink in place so it doesn’t spill and create a hazardous situation inside the spacecraft’s cabin. It holds the liquid steady even when the astronaut flips or tosses the cup. Though the crease contains the liquid, it has a dual purpose: It also allows the liquid to move out of the glass via surface tension when the astronauts want to drink. “Wetting conditions and the cup’s special geometry create a capillary pressure gradient that drives the liquid forward toward the face of the drinker,” said mechanical engineering professor Mark Weislogel of Portland State University. “An astronaut can drain the cup in sips or one long gulp in much the same manner as on Earth.”

Japanese astronaut Kimiya Yui and NASA astronauts Scott Kelly and Kjell Lindgren have been using the cups to drink both hot and cold beverages. The astronauts were surprised that they worked and were overall pleased with the drinking experience, says the researchers. Responses to the new cups include, “Hey, you can smell the coffee,”and “This is eerily like drinking on Earth.” The NASA-lead team presented the initial results of this capillary flow experiment during this week’s annual meeting of the American Physical Society’s Division of Fluid Dynamics in Boston.