According to its creators, this technology could enable even something as complex as a smartphone to be 3D printed using a single machine: right from the outer casing to the printed electronic circuit boards that make it run. As well as your standard metals and plastics, it can also manipulate liquids with precision.

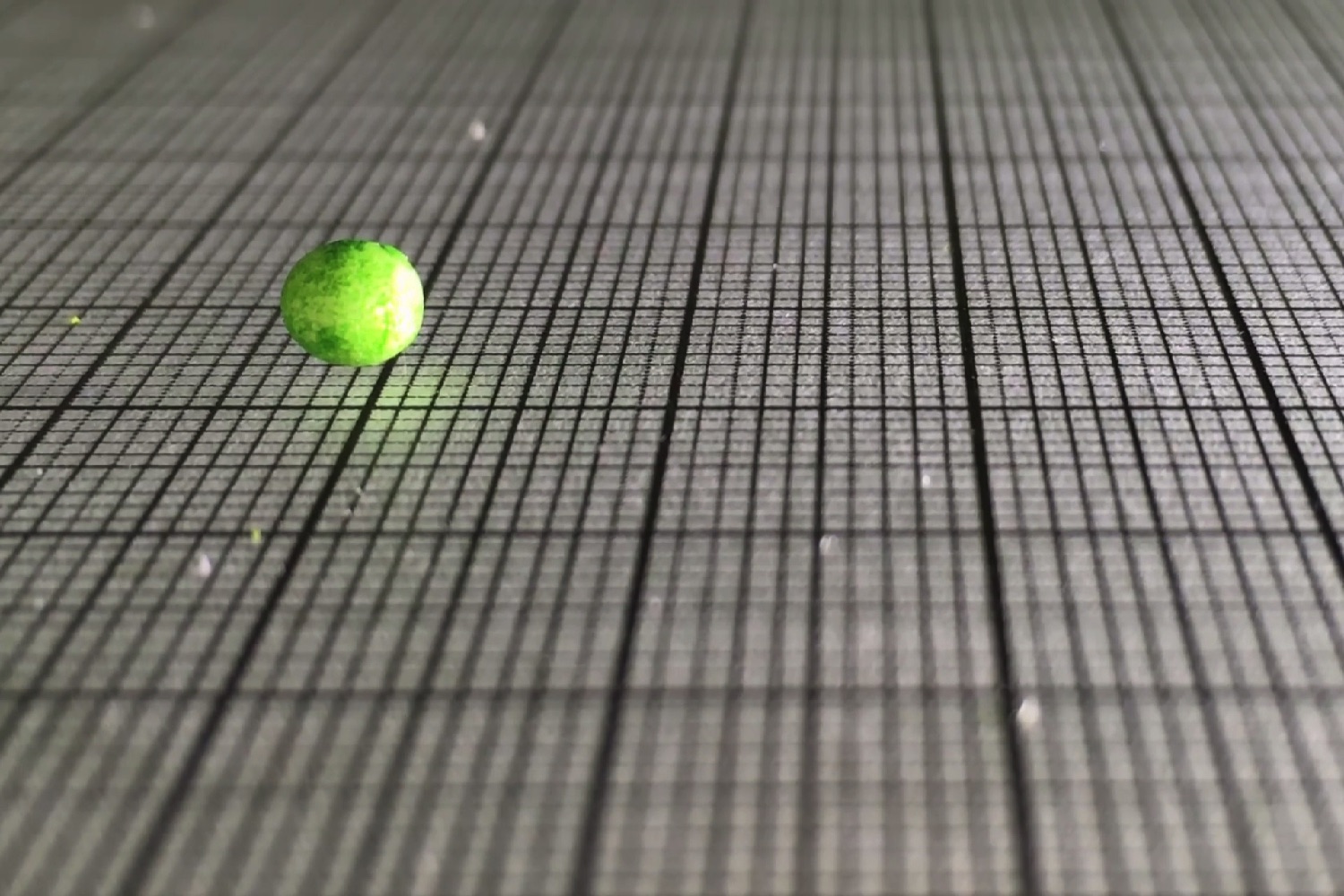

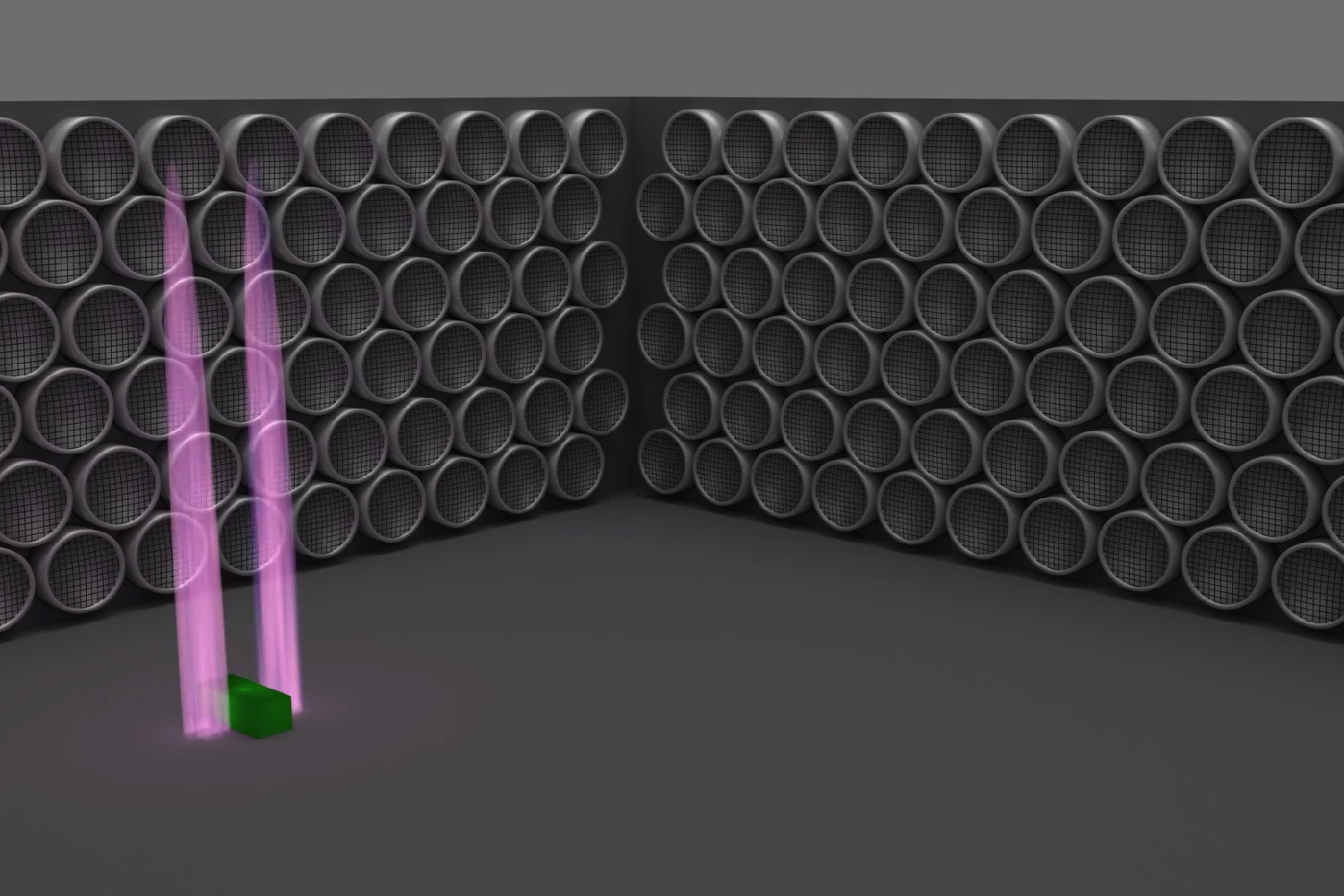

“The apparatus uses an array of ultrasonic transducers that emit ultrasonic waves,” lead researcher Osvaldas Putkis told Digital Trends. “By having individual control of each transducer, it is possible to create desired pressure profiles that can trap, rotate and move particles and components without touch. The non-contact nature of ultrasonic manipulation offers a few important advantages when compared to mechanical handling. It can handle a wide range of materials having very different mechanical properties, from plastics and metals down to even liquids. It can [also] handle sensitive materials and small components, avoiding the parasitic electrostatic forces.”

The physics behind the machine are pretty darn complex. However, if it works as well as the demo seen in the above video, you should be able to manipulate a wide range of particles in such a way that your created object forms together like a reassembling liquid metal T-100 from Terminator II. The company claims that its accuracy in moving objects is in the range of just a few microns.

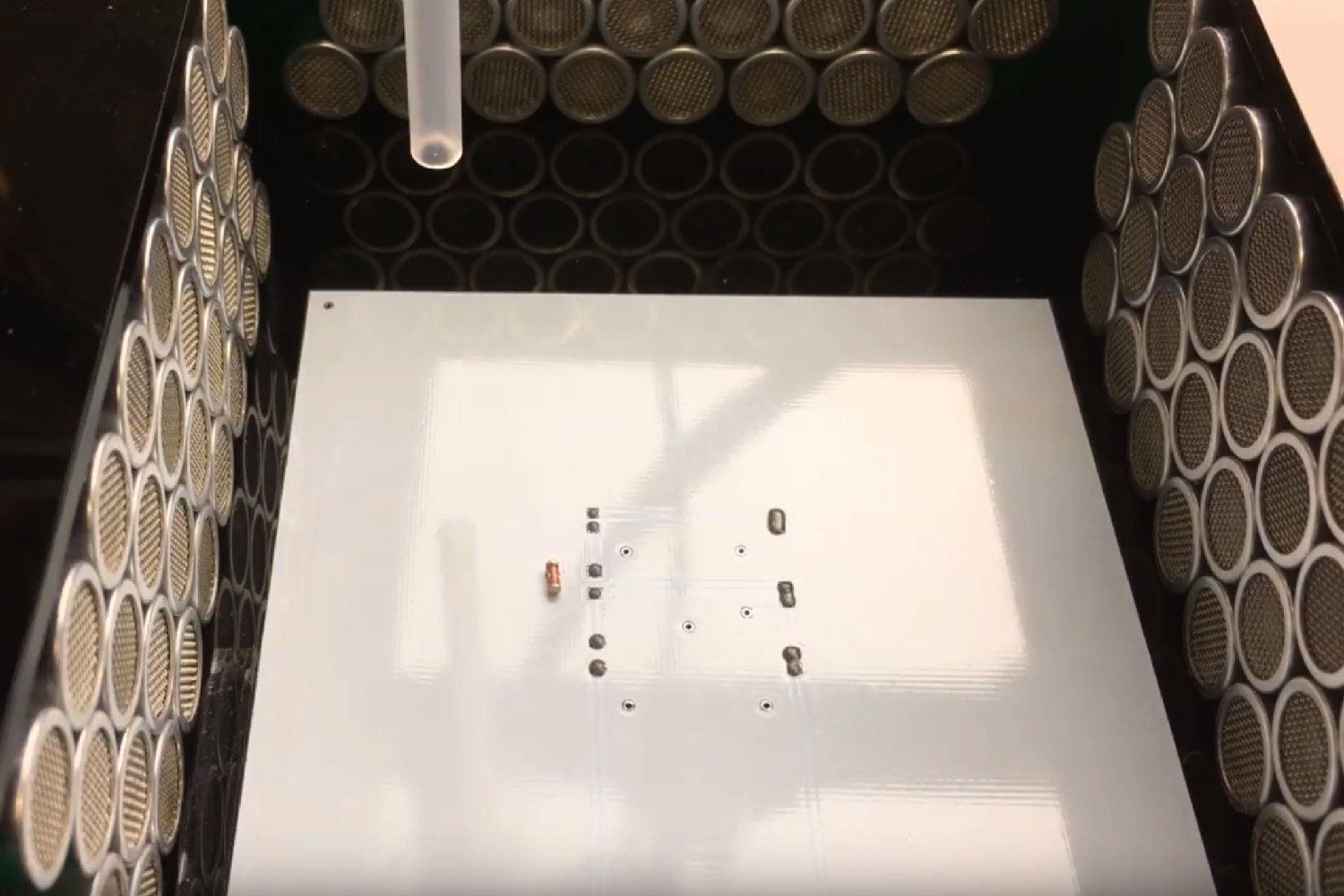

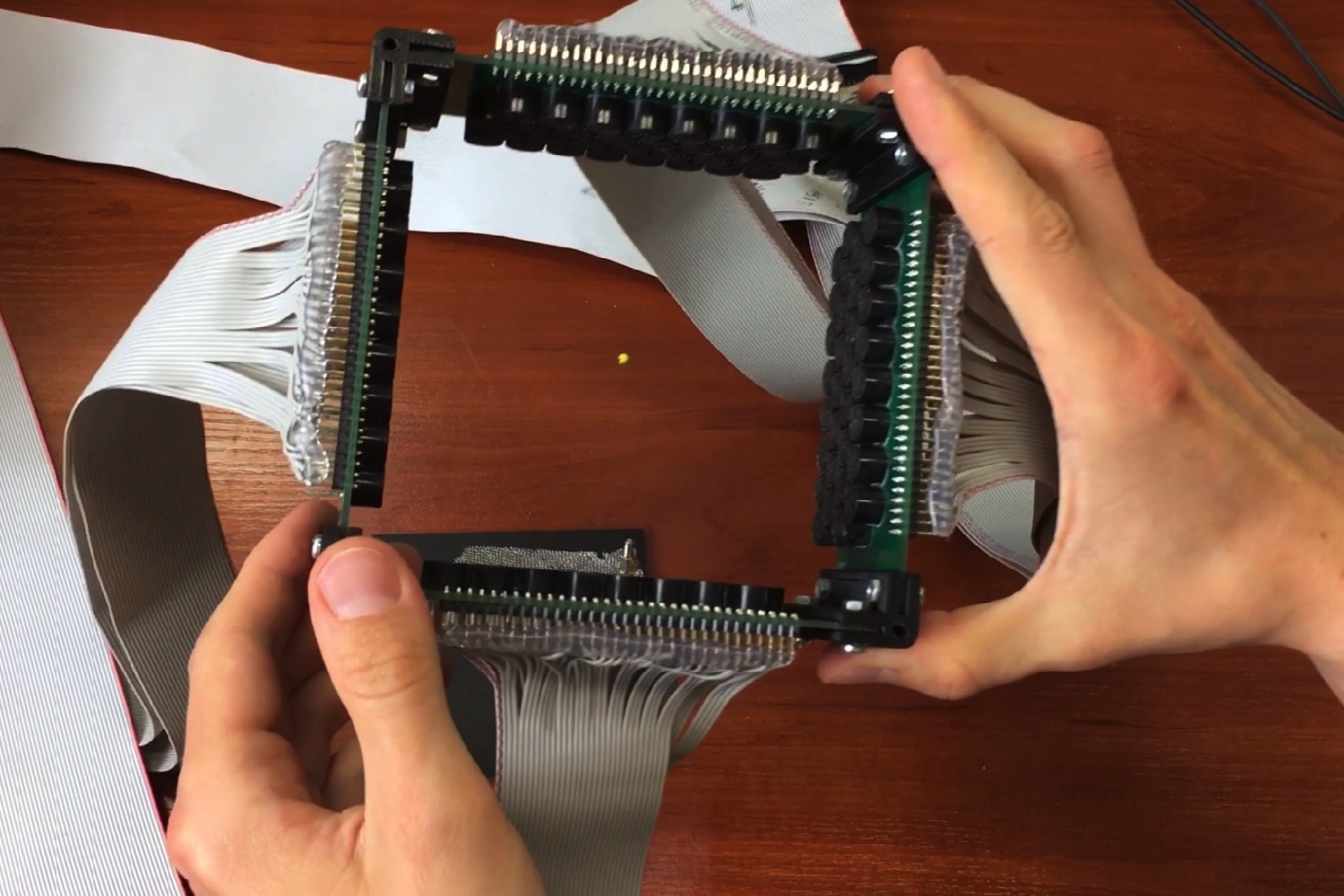

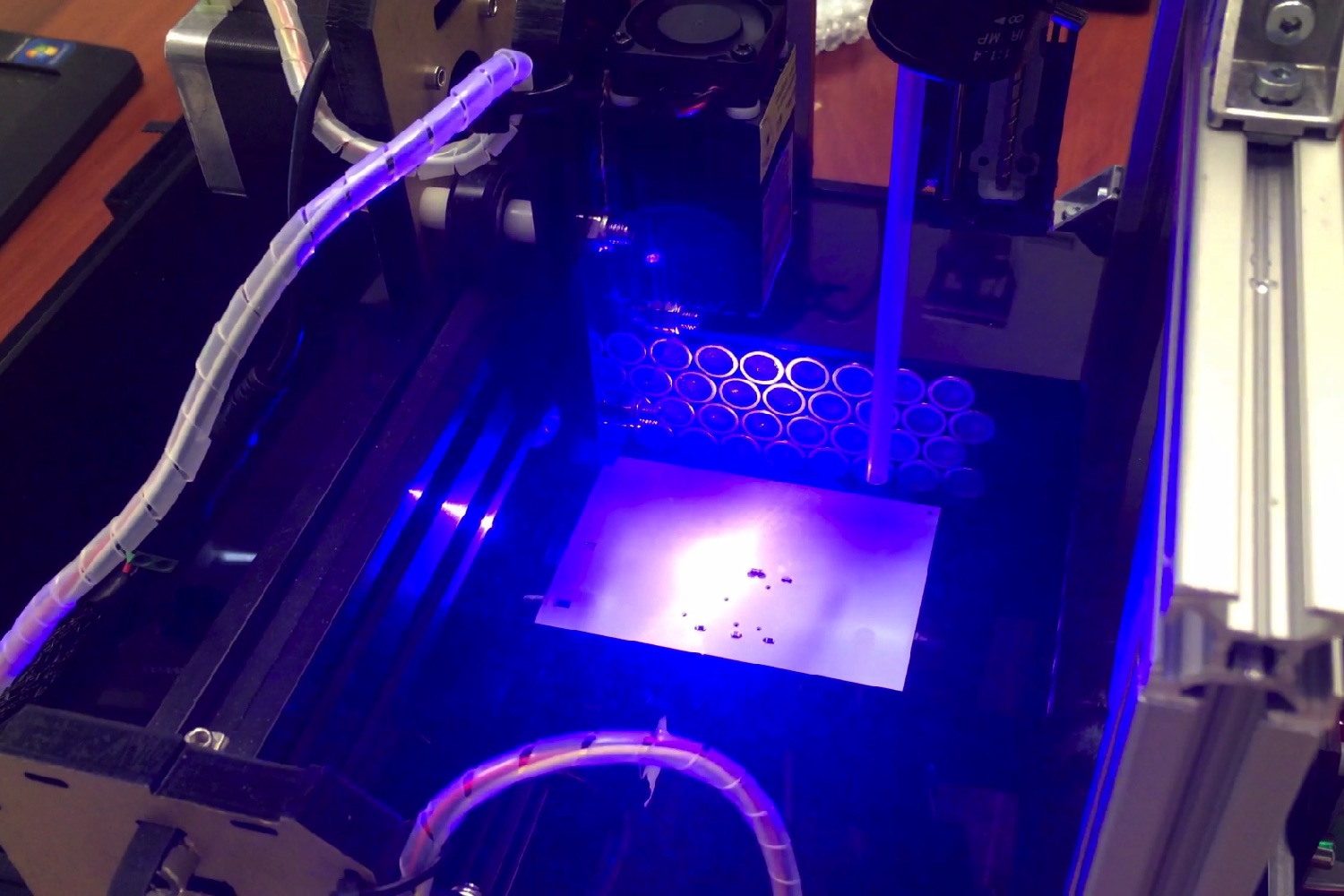

At present, Putkis says his team has developed an early prototype, capable of assembling simple electronic circuits on a printed circuit board. To do this, it employs non-contact ultrasonic manipulation technology for positioning of the different electronic components, as well as a laser to solder them in place. To coordinate the process, calibrate the laser, and detect the various components, it uses an on-board camera.

“At this stage it is very hard to say when such printer will be available as an end-user product as there still needs a lot of research and development to be done,” Putkis said. “We are seeking partnerships that could potentially help speed up the developments and application of this printing method.”

In other words, it could be a bit of a wait until you’re printing off the new iPhone at home, rather than queuing to pick one up from your local Apple store. If Neurotechnology’s research pays off, though, this could be a serious game-changer — even in an industry that’s bursting at the seams with high-quality 3D printers.