APWorks specializes in additive layer manufacturing (ALM) and special materials, producing optimized special parts for the automotive, aerospace, and robotics industries. The Light Rider is its first motorbike.

Constructed out of aluminum alloy particles, printed in thousands of 60 microns thick layers, the frame for the bike uses a branched hollow structure. It looks like an organic structure, perhaps something you’d see under a microscope. The aluminum alloy is a proprietary design called Scalmalloy that resists corrosion and is strong as titanium. The material and design resulted in a frame that weighs only 13 pounds but can handle the load and rigor of daily use. The total weight is 77 pounds — 30 percent of a conventional electric motorbike.

The Light Rider is powered by a 6kW electric motor capable of accelerating from zero to its 50 mph (80 kmph) top speed in seconds, according to APWorks. The range is 37 miles (60 km) on a charge.

There is no announcement about whether APWorks intends to go into volume production of the Light Rider. However, if you’re intrigued enough to want to get on the list, the company is taking pre-orders for a limited production run of 50. But grab a large pen when you pull out your checkbook: Those 50 Light Riders are priced at $56,095 each (€50,000), plus tax.

Now that Airbus and APWorks have shown the way, it’s a fair bet that other electric motorbike and larger motorcycle makers will be looking into 3D printed frames as well.

Editors' Recommendations

- Nvidia turns simple text prompts into game-ready 3D models

- 3D printed cheesecake? Inside the culinary quest to make a Star Trek food replicator

- This is how you can accidentally kill AMD’s best CPU for gaming

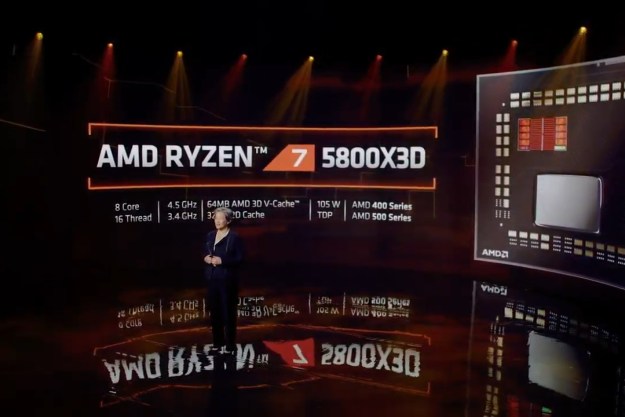

- AMD Ryzen 7 5800X3D beats predecessor, but AMD promised more

- AMD’s revolutionary 3D V-Cache chip could launch very soon