Printers are one of those “classic” technologies that have had minimal innovation – just more touchscreen interfaces, slots for various memory cards, and better Wi-Fi connection. The only things that truly changed are higher image quality and faster performance, but the concept of putting ink to paper remains the same. One of the most frustrating things about larger printers is how they never seem to function past two weeks without a paper jam, causing you to open up every compartment of the machine to see where the paper got lodged. That’s where the Stack aims to reinvent printer designs.

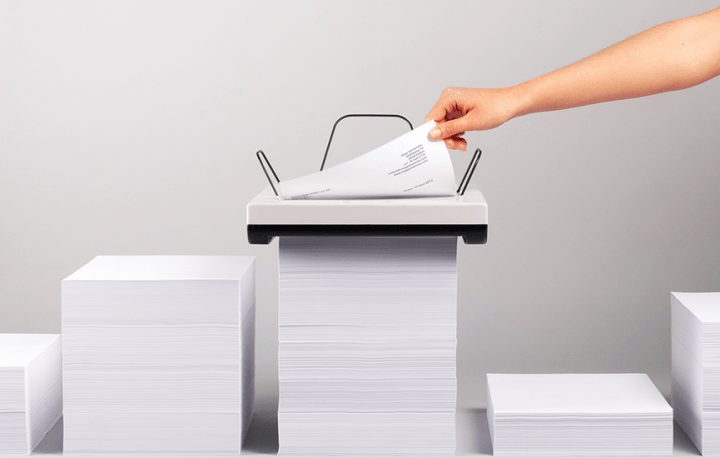

Unlike most traditional printing machines, the Stack does not require users to load blank paper packs. Instead, just put the machine on top of a pile of paper and it will eat its way down the tower until it reaches the bottom. The Stack strips the classic printer design down to just the tray, and incorporates inking capacities around that shape. It also eliminates the surprise of “Oops, you’re out of paper” when you can see exactly when the supply has diminished.

The machine is currently a working prototype – which is good because we still have some concerns with the initial design. As far as we can tell, the Stack will suck up paper, then spit the printed piece out on top. If you are printing a large document, how will the last few pages fit above the printed stack? Will the machine be heavy enough to keep the pile of paper in place, or will they blow away on breezier days? We already know the printer comes sans-scanning, but could the functionality be incorporated into the top of the tray?

So many questions, not enough time for Yamamoto to address. The designer says he is still tweaking the prototype and just wanted to design a machine that’s less bulky and requires minimal reloads. He is currently looking for major printer manufacturers to help refine the product so they can put it to market. Anyone else think Canon, Epson, or HP should take the bait?