Ever since the original 3Doodler 3D printing pen made its debut on Kickstarter, the company behind it has been hard at work developing new-and-improved iterations of the same idea. There’s the slimmer, smarter 3Doodler Create, as well as a low-temperature 3Doodler Start that’s designed for children. But today, the company pulled the curtain back on its most advanced product yet: the 3Doodler Pro — so we stopped by for a demo at IFA in Berlin.

The only downside to all these fancy new features is that they make the 3Doodler learning curve a tiny bit steeper.

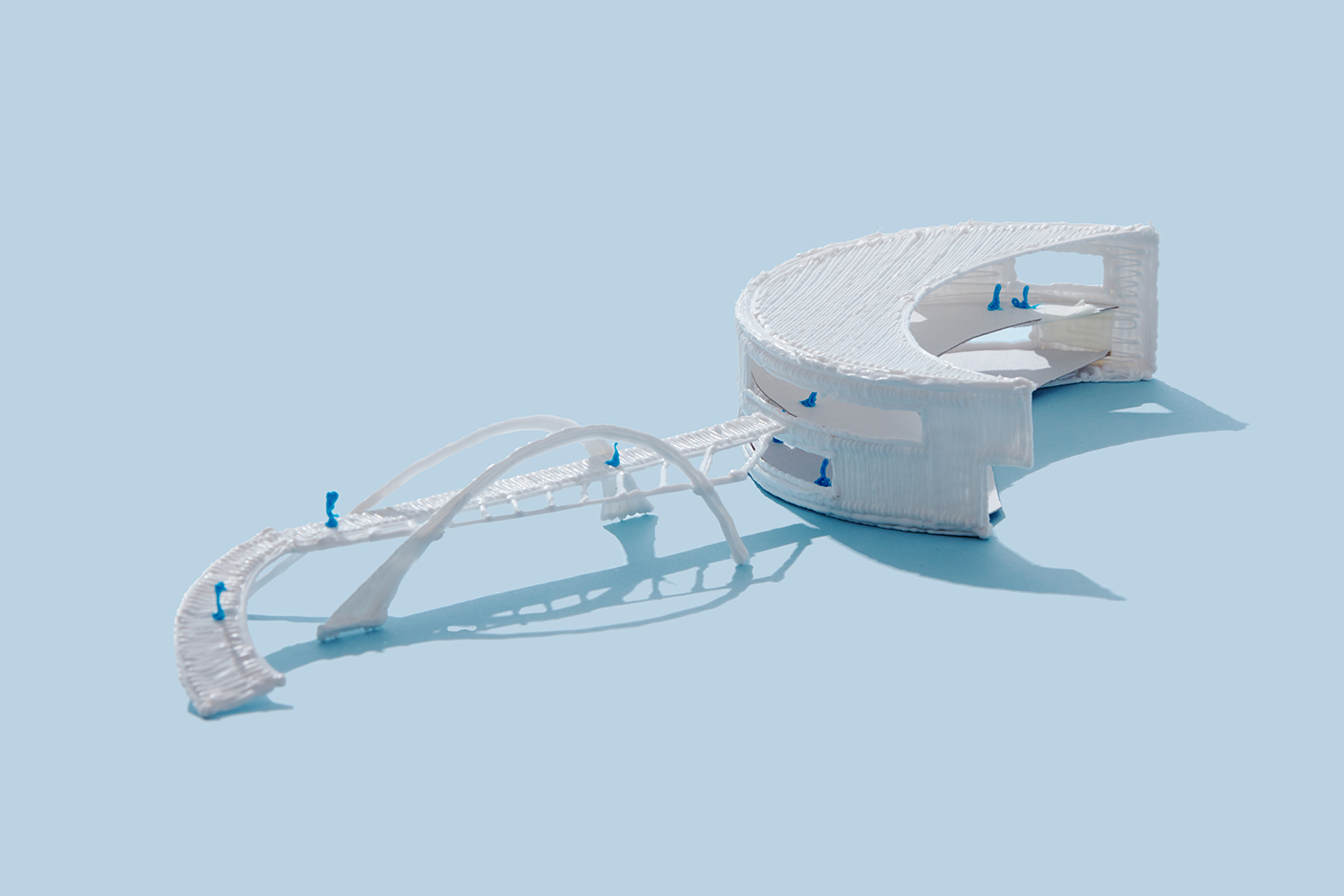

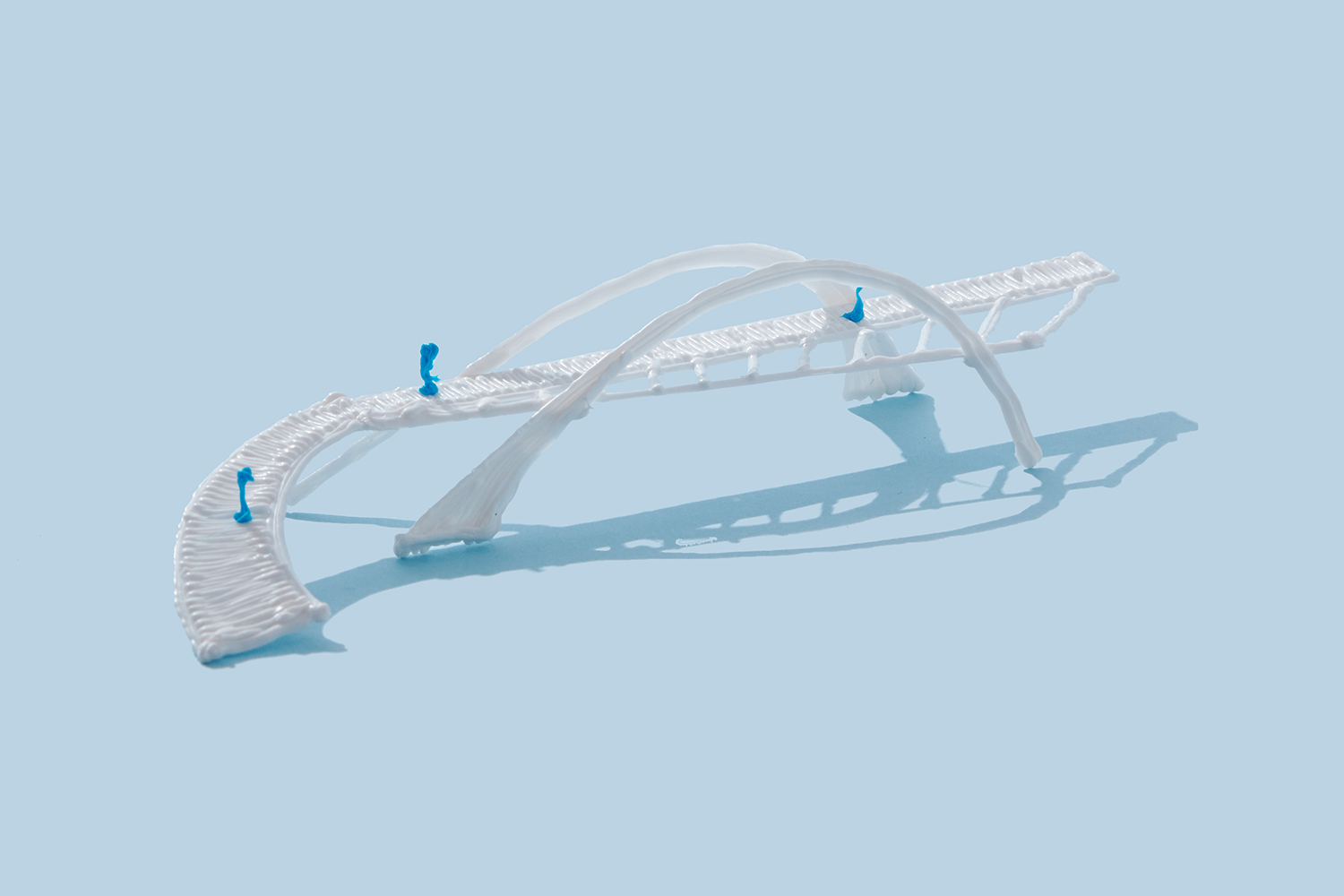

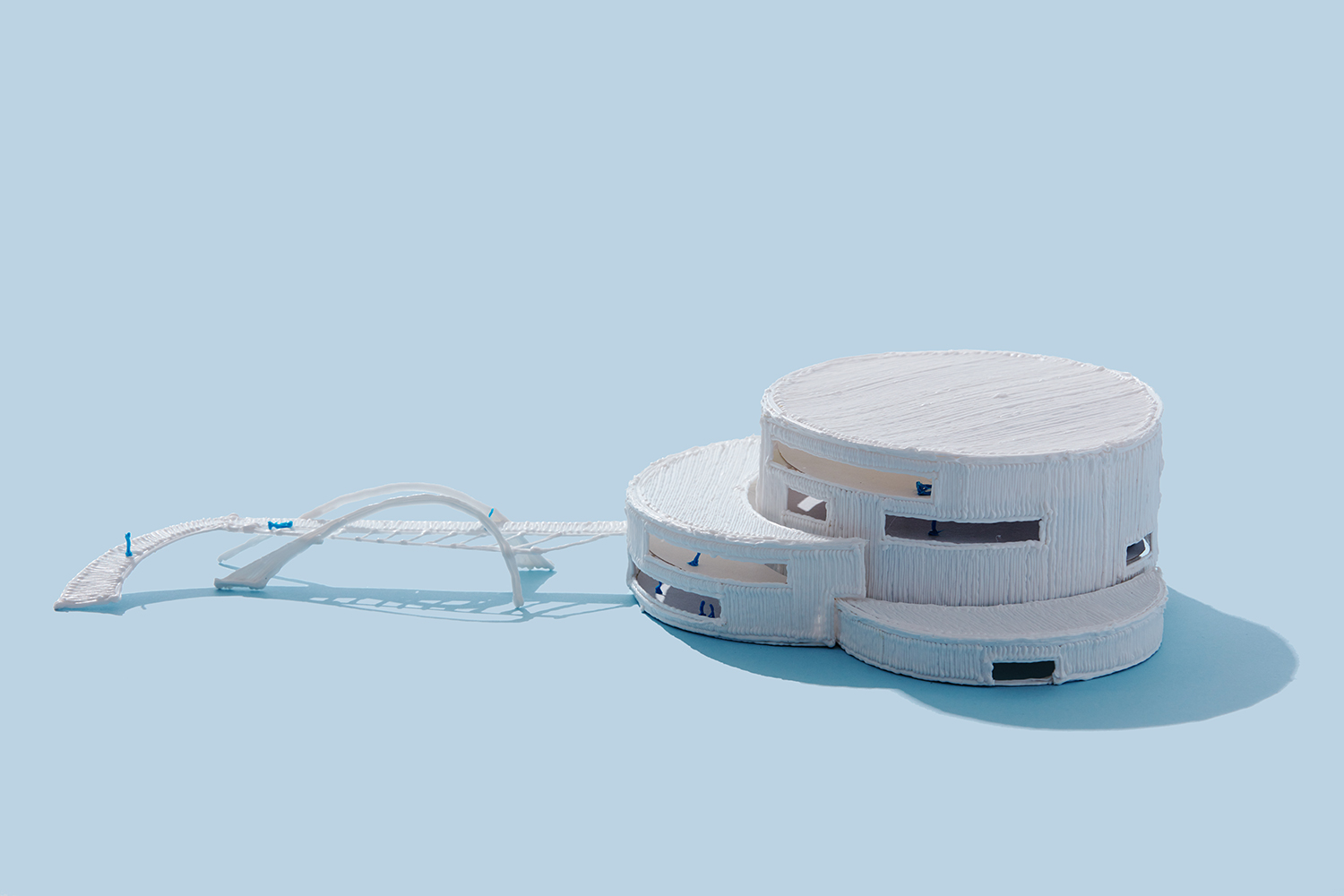

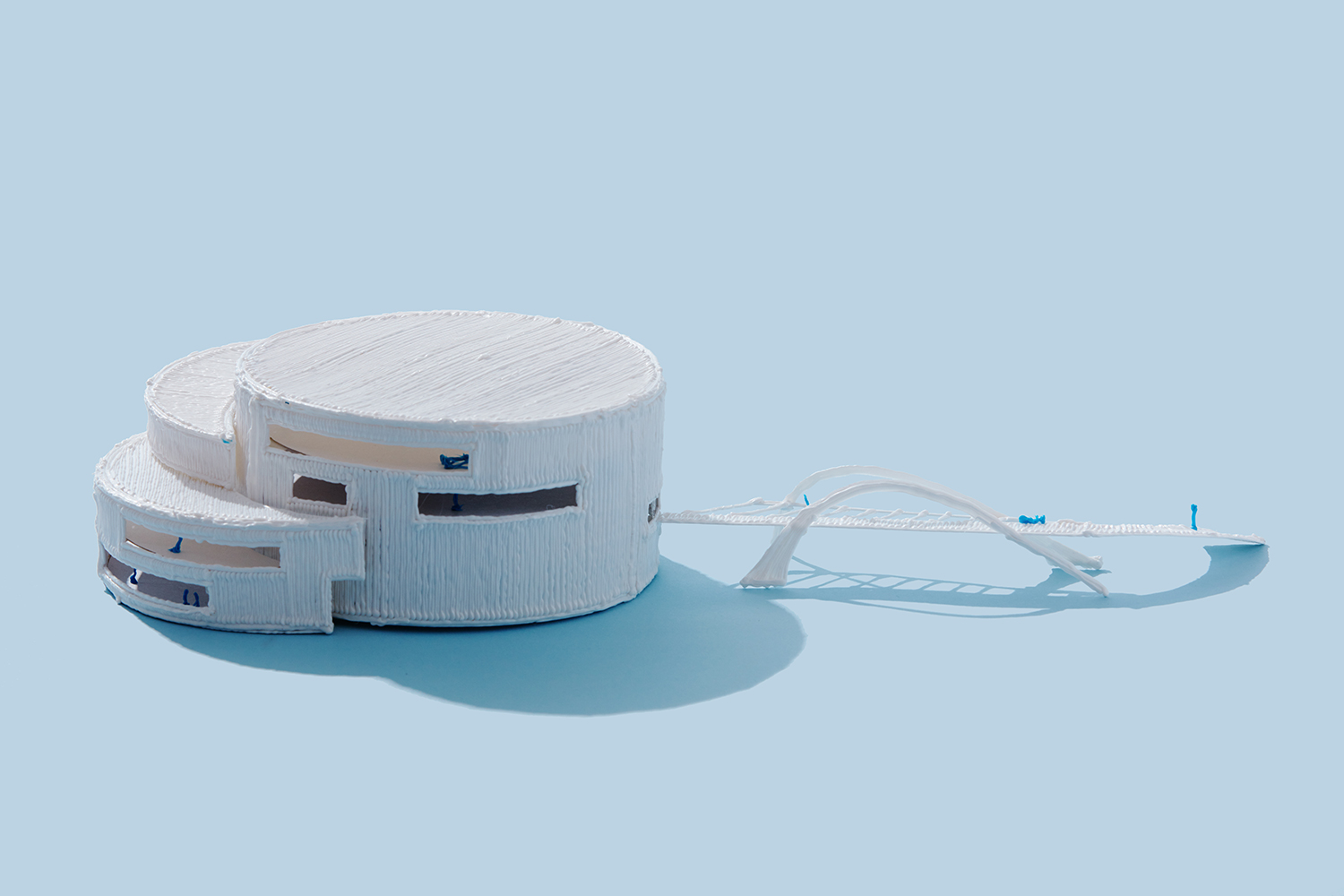

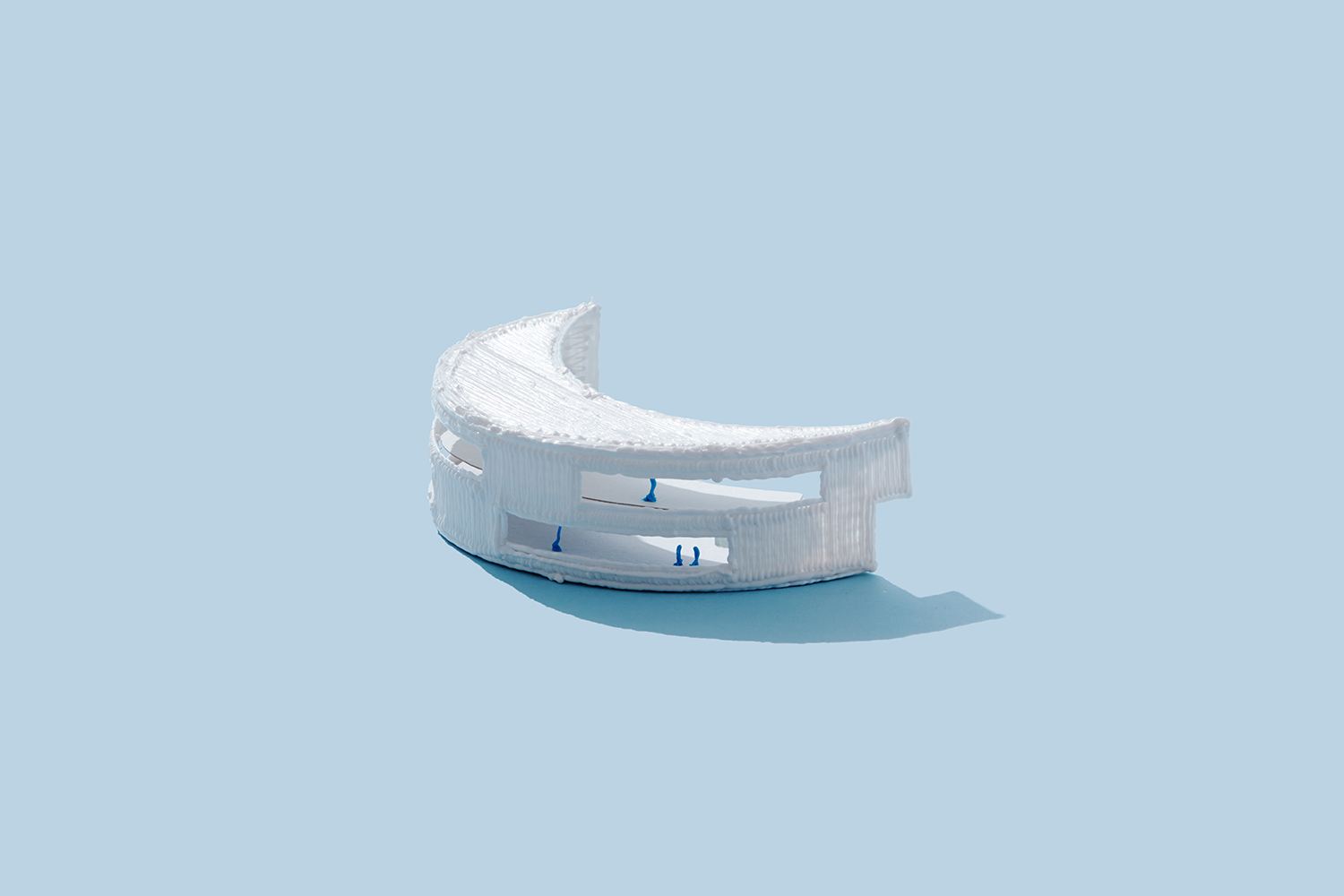

As expected, the Pro is essentially just a souped-up version of the original 3Doodler, so despite all the bells and whistles on this iteration, it still works more or less like a fancy hot glue gun. To use it, you shove a stick of thermoplastic in one end and drive it through a hot metal tip on the other end, effectively turning the plastic into a viscous goop that solidifies shortly thereafter — thus allowing you to draw in three dimensions.

Fundamentally, it’s the same product as it’s always been — but what sets the 3Doodler Pro apart from its forebears is the fact that it can print with a wider range of materials, and also offers a higher degree of control over parameters like heat and extrusion speed. Whereas 3Doodler’s earlier products typically featured one or two speeds and only printed with basic thermoplastics, The Pro model works with wood composite, bronze composite, nylon, and polycarbonate filament. It also boasts new adjustable dials for temperature and speed, as well as variable fan speeds for improved control over the rate at which the extruded plastic hardens.

“Beyond the numerous upgrades, what really makes the Pro so unique is how the device and materials come together to answer the needs of professionals,” says Maxwell Bogue, 3Doodler’s Co-Founder & CEO.

“When we started the 3Doodler journey back in 2013, we had world-leading architects telling us ‘I want to do this.’ ‘This’ was a quick wave of the pen in the air, with plastic solidifying in its wake. With new materials like polycarbonate that dream is a reality. The high-performance pro can be used for the most advanced of purposes to bring concepts to life, and become an integral part of the creative process.”

The only downside to all these fancy new features is that they make the 3Doodler learning curve a tiny bit steeper. We took the pen for a spin at IFA, and while it’s definitely easier to draw with once you’ve got the settings right, getting the settings right in the first place requires a fair bit of knowledge. Ideal temperature and extrusion speed settings differ depending on which filament you’re using, so it takes a bit of fiddling around to figure everything out. CEO Max Bogue assured us, however, that the pen will ship with a handy little chart that helps new users get off on the right foot.

As of September 1, 3Doodler Pro is available starting at $249 — first from the MoMA Design Store, and then from number of other stores like Barnes & Noble, Macy’s, Amazon, and 3DoodlerPro.com.