Full-color 3D-printing giant WhiteCloud has launched a new medical 3D printing service called 3DyourSCAN: offering personalized full color pre-surgery educational models based on a patient’s CT/MRI scans. Most impressively of all, these individual models can be turned around as quickly as 24 hours.

“There is still a really big barrier when it comes to communicating and understand what is going on inside the body,” Braden Ellis, WhiteCloud’s chief revenue officer, told Digital Trends. “This process really changes people’s perspective on what personalized healthcare can be. It’s now possible to give people a truly visible interaction with what’s going on inside themselves, prior to surgery. It provides the patient — who doesn’t have training to read MRIs or CAT scans — an understanding of what they’re facing, and why surgery may be the right route for them.”

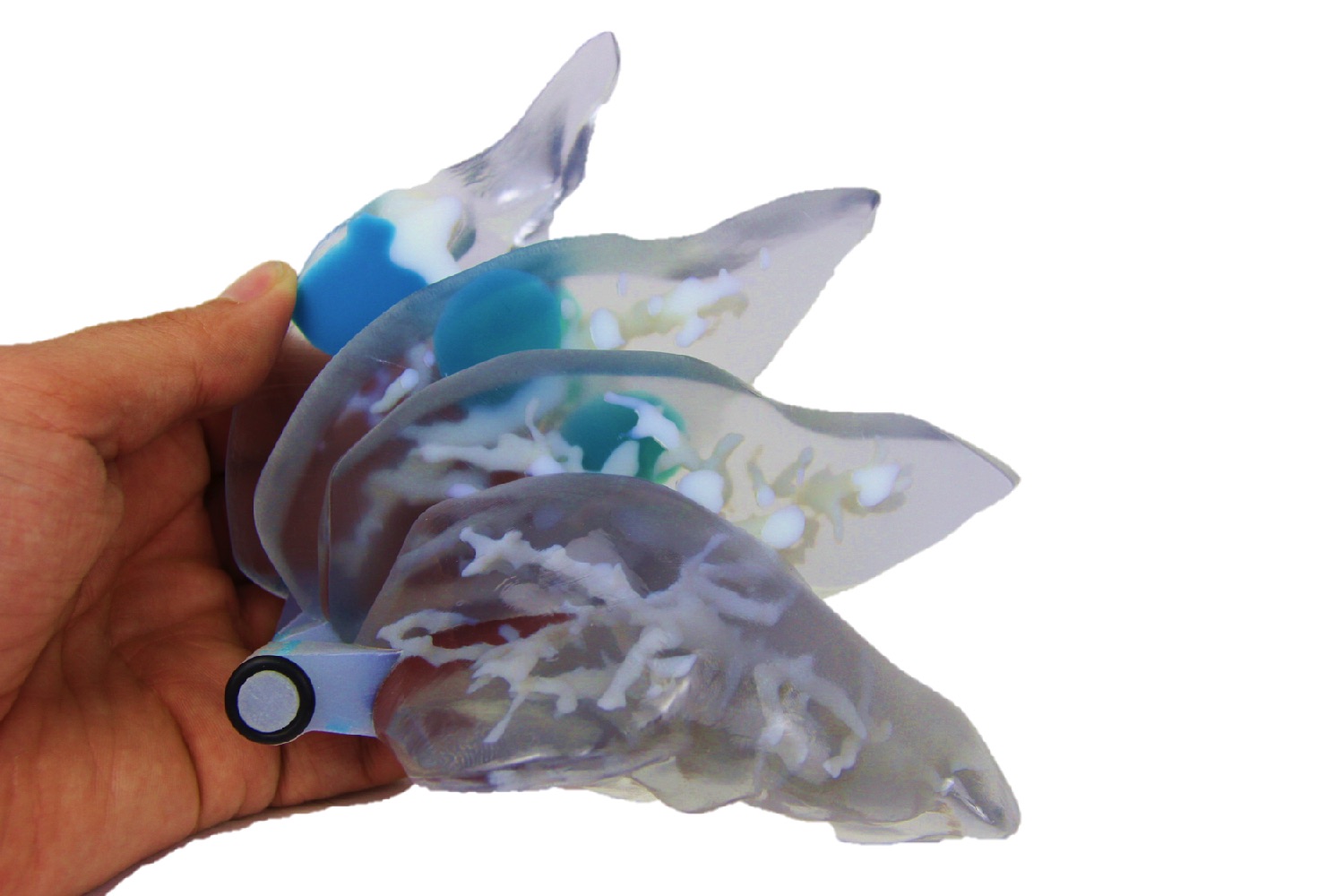

3DyourSCAN involves a proprietary “Hinge & Slice” system, able to provide a cross-section — connected by a hinge — to show what’s going on inside a particular body part. The technology is a partnership with advanced visualization software company TeraRecon.

“It’s mind-blowing to see what can come out of these printers,” Ellis continued. “Color is a really big aspect. Single color prints don’t really highlight the areas of interest. TeraRecon has incredibly incredible algorithms for color shading. It gives a sense of true realistic color; much like what a surgeon would be seeing. It makes it much more relatable for people.”

He explained that, while other companies have previously offered custom models of organs, these can take three to five weeks to create due to the manual processes involved. That is something that 3D printing — and a company with the resources of WhiteCloud — can help change.

“The turnaround time is really important,” he said. “With instant gratification services like Amazon Prime setting the bar of expectations for what people expect with delivery, we knew that this was key. With the capacity and technology that we have, our factories are able to handle thousands of objects every day — personalized and customized for individuals.”

And while services like Amazon Prime will rush the latest Game of Thrones boxset to our door, Ellis noted that in the medical world this takes on added importance.

“We see the need for this to be quick, because surgery often can’t wait,” he noted. “If it’s a knee surgery there may not be a huge rush, but if you look at children’s heart surgery or [operations to remove] brain tumors, these are things which are needed to be handled rapidly.”

In all, it’s just another way that 3D printing — and the industry leaders within it — are changing the world for the better.