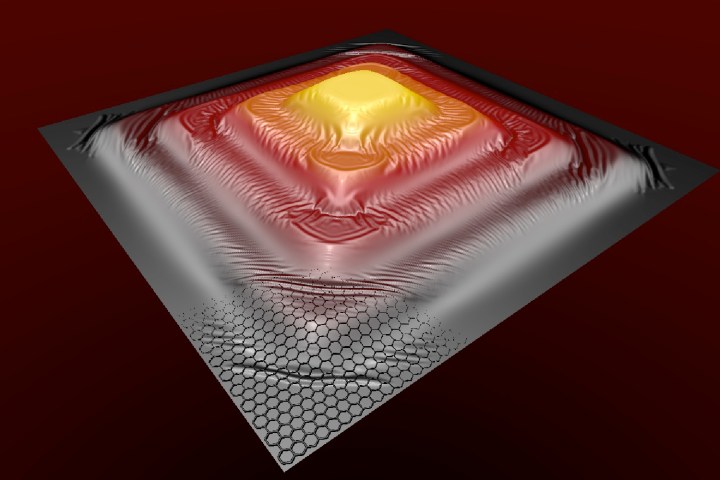

That’s easier said than done, but researchers from Finland and Taiwan may have it cracked. What they have discovered and demonstrated is a way of “forging” graphene into three-dimensional objects by using a focused laser beam. As a proof of concept, they showcased how lasers could create a 3D pyramid out of graphene. To achieve this result, a laser is focused on a point on a 2D graphene lattice, which irradiates that part of the structure and causes it to bulge. The 3D pyramid the team created is just 60 nm in height (that’s small enough to fit onto a single strand of human hair), but still 200x taller than the graphene sheet.

“This changes the electronic and optical properties of graphene, opening a new way to tailor the properties with a very simple method,” Professor Mika Pettersson, who led the research team at the Nanoscience Center of the University of Jyvaskyla, Finland, told Digital Trends. “This changes how graphene devices can be designed and fabricated. As an important aspect, the properties can be tailored locally, but still maintain the integrity of the carbon network. Ultimately, the vision is to fabricate functional devices with the laser writing method.”

Pettersson said that the next goal is to delve into the atomic-level structure of the 3D material, in order to better understand its electronic and optical properties, and how these differ from plain old 2D graphene. After that, the development of applications can follow. “We think that there is great potential for real-world applications,” Pettersson said. “Many of them are in the same fields as for normal graphene: flexible and transparent electronics, optoelectronics, and sensors, but this time with a possibility to design 3D device architectures.”

Should all go according to plan, hopefully we’ll see more groundbreaking examples of graphene being used outside of the confines of research labs. A paper describing this work was recently published in the journal Nano Letters.