You may associate McLaren with supercars bearing the same name or the McLaren Honda Formula 1 racing team.

The McLaren Group has many divisions, however, often developing or using technology from each other. McLaren Applied Technologies designs innovative performance breakthroughs in a variety of fields, including health technology. “Progressive collaborations” is a term straight from the group’s mission statement.

According to McLaren’s Chief Medical Officer Dr. Adam Hill, “From digital therapeutics to tailored human performance programmes and bespoke medical devices, our aim is to innovate healthcare solutions that can be tailored to individual patients.

“The common thread in all of our projects is data. We use data to build a digital picture of how a patient is performing or recovering, and then create solutions, or in the case of the Project Invincible, devices, to aid our users.”

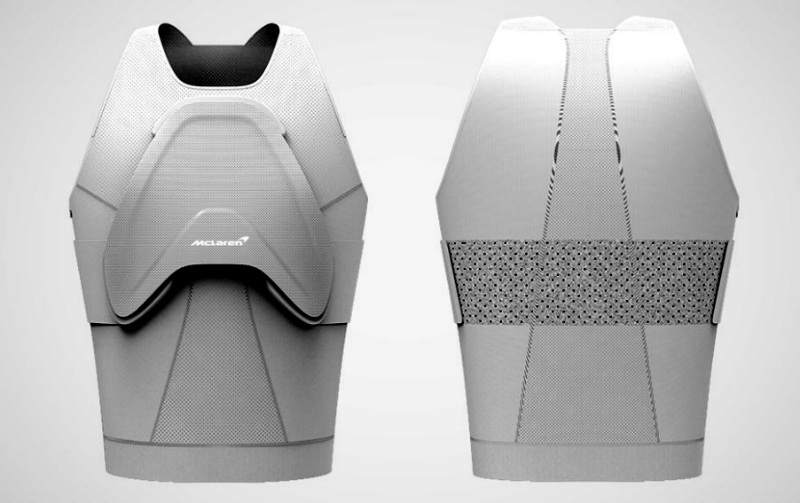

The Invincible shield’s primary job is to protect the heart and lungs, augmenting the function of the rib cage. The shield’s materials also protect against low-energy impact. So while that sounds like McClaren’s body armor isn’t intended to stop bullets, it will deflect a myriad of other impact sources.

The wrap-around vest-like shield uses high-failure strain Dyneema fibers often used in body armor to contain damage. Woven fabric with a highly toughened resin system resists impact. Zylon fibers, employed in all F1 cars to protect against side penetration, and rigid carbon fibers enhance load-carrying capacity and flex resistance.

The result pulled all the above technologies together in a unique fashion. “The Invincible shield is made from materials that will be in next year’s Formula 1 car,” Hill said.

The client wanted a discrete everyday garment that could be worn under a shirt. McLaren’s team produced what is maybe the ultimate bespoke vest with the client’s specific requirements and exact internal and external body imagery.

With that data and continued client feedback availability, the team utilized in-house resources for mechanical engineering, industrial design, and specialty composites. The end solution “was designed completely around the user, and was entirely data-led — it delivered on every level because the team had listened to the data throughout. True data-driven design,” according to McLaren’s website.