Thanks to wearables like the Apple Watch, there’s no doubt that our timepieces are getting smarter and more high-tech. However, if you really want an attention-grabbing way to tell the time (albeit a slightly less convenient one), look no further than student Görkem Bozkurt’s amazing 3D-printed clock. Based on a “rolling ball clock” design by Harley Mayenschein dating back to the 1970s, it tells you where you are in the day courtesy of a smart rail system, some marbles, and a whole lot of 3D-printed components.

The clock features three rails: One row for hours, marked 1 to 12; one for 5-minute increments, marked 5 to 55; and one for single minutes, marked 1 to 4. As balls are dumped from one level the next, the number of balls on each level enables you to work out the time using a spot of basic math. It sounds complicated — but it really isn’t after you get used to it. (More instructions on how to tell the time with one of the contraptions can be found here.)

Over the years, we’ve seen a number of projects re-creating Mayenschein’s original clocks, ranging from Lego versions built by fans to new wooden versions made by Harley’s son, Joe. Bozkurt, a physics student at Turkey’s Bilkent University, is the latest to throw his hat in the ring with his 3D-printed version.

“When I was a kid, I was fascinated by small moving mechanisms,” Bozkurt told Digital Trends. “Because of this, I was a fan of novelty stores. This is when I first saw the rolling ball clock. It was different than the other kinetic toys I loved watching because it [performed a function by telling you the time.]”

Bozkurt’s model is a nifty reimagining of the original. In an effort to make it more visually appealing, he has added some new features, such as a different elevator mechanism. Best of all? If you like what you see, you can create your own version since Bozkurt has shared the instructions online.

“I share all my projects with the creative commons license, so people can improve them and edit them as they wish,” he continued. “The feedback I get from the community is the most important aspect of this. People can point things out that I’ve never thought about. Everyone who knows how to use a 3D printer should be able to build it. I provided instructions in detail to guide anyone with little to no experience. The build should take around one day to print, and 15 to 30 minutes to assemble.”

Hey, to butcher an old phrase, you’ve got to spend time to make time!

Editors' Recommendations

- Nvidia turns simple text prompts into game-ready 3D models

- 3D printed cheesecake? Inside the culinary quest to make a Star Trek food replicator

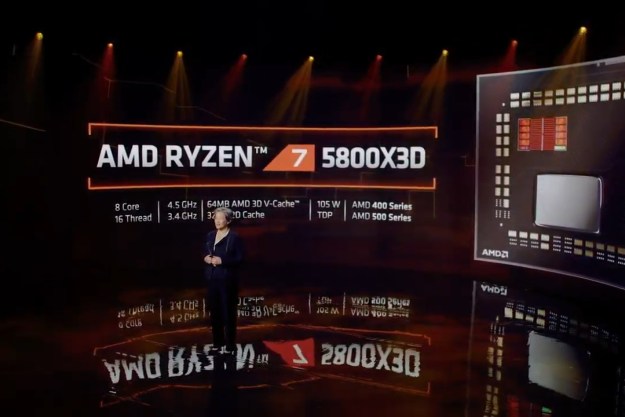

- AMD Ryzen 7 5800X3D beats predecessor, but AMD promised more

- AMD’s revolutionary 3D V-Cache chip could launch very soon

- AMD teases performance of its revolutionary 3D V-cache chip