When exotic animal veterinarian Nicola Di Girolamo received a badly injured pet tortoise called Uga, he turned to cutting-edge additive printing methods to save its life.

“As part of my job, I unfortunately see tortoises which have been injured,” he told Digital Trends. “Uga had been attacked by rodents, which had bitten her hind legs. Her owner, a young girl, was very upset. I had the tortoise in my practice for around one month, trying everything to avoid having to amputate the hind legs.”

Sadly, while the staff in the clinic were able to rehabilitate one of Uga’s legs, the other was too badly damaged and had to be amputated. At this point, Di Girolamo decided to get in touch with local 3D-printing hub, Roma Stampa, whose owner Massimo Mostosi was keen to get involved. They took measurements of Uga and then used these to create a 3D-printed prosthetic device, which essentially acts as a wheeled cart to help the tortoise move around. The wheeled prosthesis is attached to Uga’s shell by way of two neodymium magnets.

Di Girolamo said that he previously had created similar accessories for tortoises, using Lego wheels — except that these tended not to work very well due to the size difference between tortoises. The use of magnets was also new, since he had previously used velcro as a means of attachment. “That became dirty very quickly since it was on the ground,” Di Girolamo said. “We were very, very happy when we came up with the idea of using magnets and 3D printing. It made it functional and cost effective.”

Best of all is the fact that the prosthesis can be more easily attached and detached in its current guise. “Before now, the tortoise had to hibernate with its implants on,” Di Girolamo noted. “Tortoises usually hibernate for six months per year. It was very difficult for them to be in the ground, but now owners can remove the implants before hibernation takes place. Then when they wake up in the spring, their owner can very easily reattach the implant to the tortoise so it can start moving and grazing again like it was used to.”

Di Girolamo said that the operation has been a big success and that Uga is currently moving well. They plan to show off the work this October at the Rome-based Maker Faire.

Editors' Recommendations

- Nvidia turns simple text prompts into game-ready 3D models

- 3D printed cheesecake? Inside the culinary quest to make a Star Trek food replicator

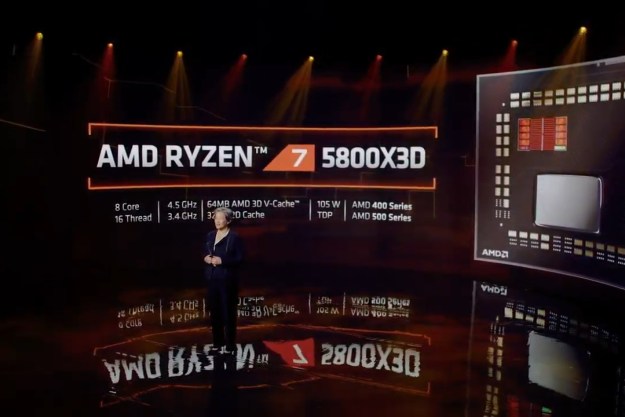

- AMD is bringing 3D V-Cache back to Ryzen 7000 — but there’s a twist

- AMD Ryzen 7 5800X3D details leak, and there’s some bad news

- AMD’s revolutionary 3D V-Cache chip could launch very soon