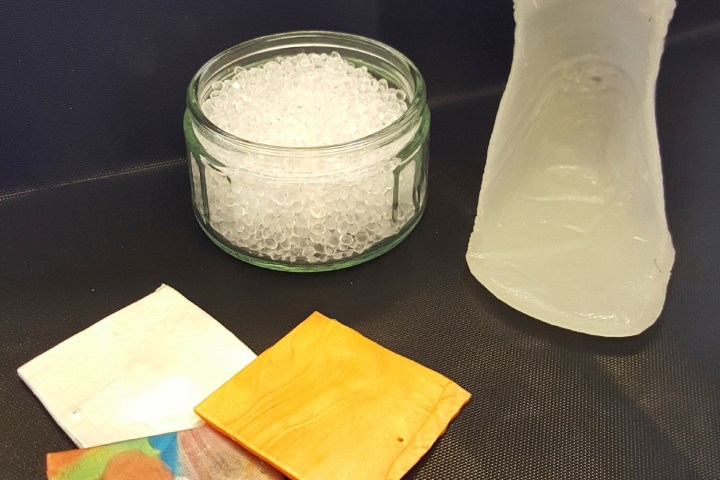

A new material developed by U.K.-based company Torc2 opens up a host of new potential applications, however — predominantly related to manufacturing tailor-made casts or splints for patients. “What we’ve developed is a blend of polymers with a low melting point,” CEO Gary Blundell told Digital Trends. “What we’re hoping to do is to replace Plaster of Paris casts with a material that can be remolded at a temperature that’s comfortable for human contact. This means that any adjustments which need to be made can be done so while the patient is wearing it.”

In short, the thermoplastics compound shifts states between a moldable, putty-like consistency at 131 degrees Fahrenheit, and a rigid, rubberized plastic state at normal body temperature. “You can move between these two states repeatedly,” Blundell said. “We’ve done tests where we heat and reheat it to make sure it’s durable.”

One advantage of being able to do this is that it cuts down on waste since it means that a 3D-printed cast could be modified as a patient’s needs change — where previously it could be necessary to remove the original cast and manufacture a whole new one.

Blundell said the company is currently preparing to carry out clinical trials, which will demonstrate to the medical field how the material could be used to the betterment of patients. He additionally notes that Torc2 is exploring other avenues, where its innovative thermoplastics compound might also be used.

“Medical applications are fairly slow-burn,” he explained. “For good reason, there are various hurdles that have to be crossed, which makes it a long process. In the meantime, we’re looking at alternative methods for bringing in earlier stage revenue. We’re not sharing any details yet, because there are non-disclosure agreements, but we’re actively looking at a variety of industrial applications.”

Even just from a “maker” perspective, a remoldable material like this could be invaluable.

Editors' Recommendations

- Nvidia turns simple text prompts into game-ready 3D models

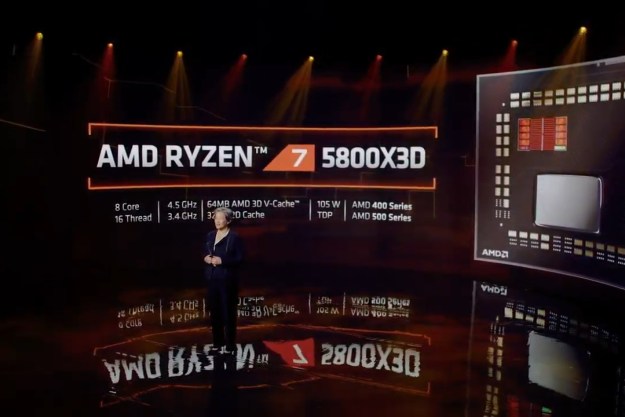

- AMD is bringing 3D V-Cache back to Ryzen 7000 — but there’s a twist

- AMD Ryzen 7 5800X3D details leak, and there’s some bad news

- AMD teases performance of its revolutionary 3D V-cache chip

- Fighting football injuries with 3D-printed, hyper-personalized pads